Sustainability at SHIBAURA MACHINE

SHIBAURA MACHINE will help to create a sustainable society through its corporate activities.

We aim to become a company that is needed by society, the environment, and our stakeholders and will create value together with them.

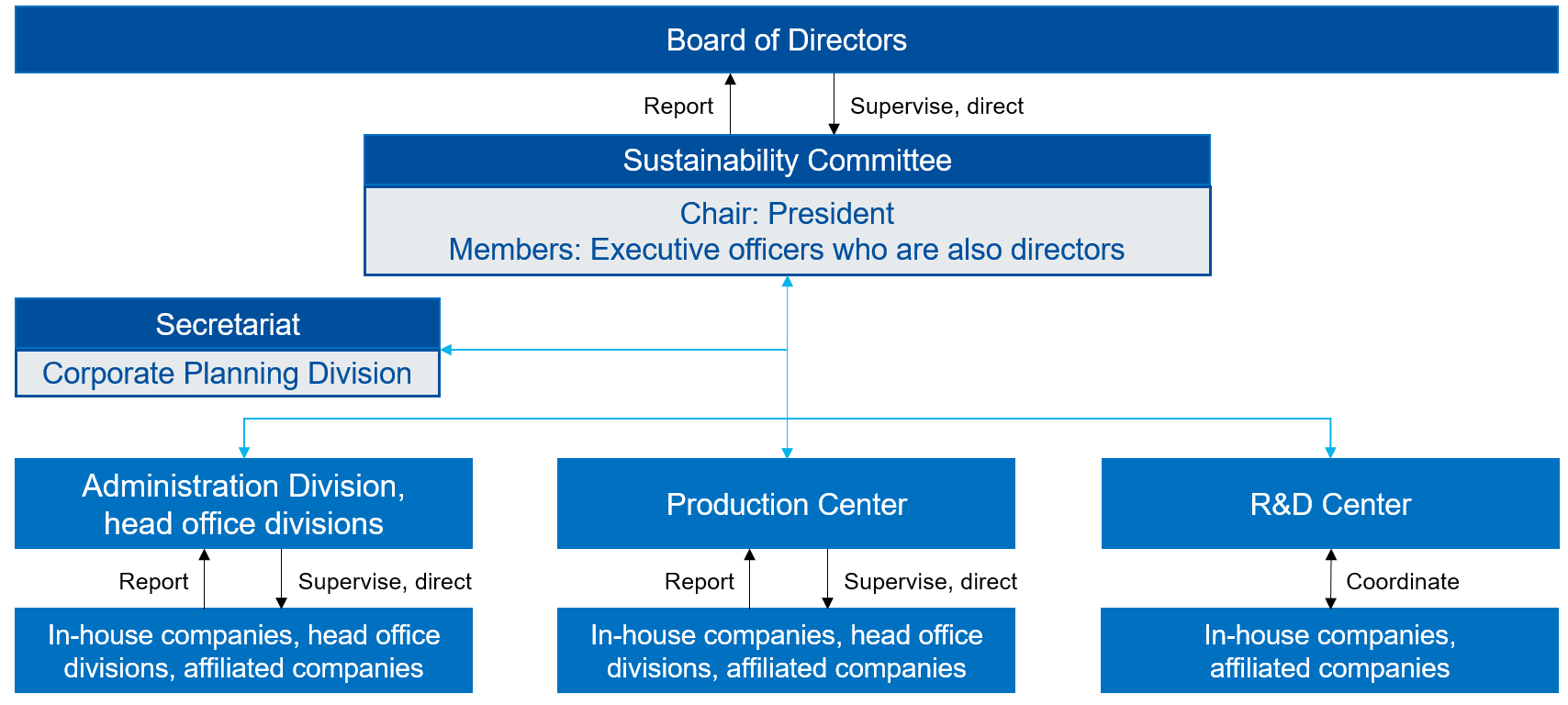

Since our company was founded, we have continued to evolve by contributing to society through "monozukuri." We will maintain our products that are based on the technology, development ability, QCD, sales, and after-sales service ability that were developed during our corporate evolution. While doing so, we will overcome changes and various risks, evolve while looking towards the future with our customers, and aim to become a company that will always be needed. Additionally, we will further improve our corporate governance and in order to further improve our corporate value, we have transitioned into a company that has established auditing and other committees. Our corporate group will help to develop a sustainable society by contributing to the solving of the various social problems set forth in the United Nations' Sustainable Development Goals (SDGs)and, thereby, play its role in protecting the rich global environment. Moreover, we will satisfy the hopes and expectations of our stakeholders because we believe that gaining their trust is indispensable, and to that end we will make even greater corporate efforts in the future.

SHIBAURA MACHINE CO., LTD.

President

Shigetomo Sakamoto

Fundamental policy of sustainability

Pursuant to our corporate principles, we are committed to realizing a sustainable society and increasing corporate value by solving issues of customers throughout the world using our technological strength, and by contributing to the development of key industries.

-

We address global social issues with outstanding technologies our company possesses to solve the issues and at the same time increase corporate value.

-

We strengthen our supply chain, taking into account the environment and human right, which contributes to sustainable use of resources.

-

We realize fair and highly transparent business management.

Activities related to the SDGs through our businesses

Achieving the Sustainable Development Goals (SDGs)

The SHIBAURA MACHINE Group will fulfill its role as a global company and aim to sustain a rich global environment and society. Through our businesses, we will try to make contributions to solve the social problems set for in the SDGs of the United Nations.