Environmental considerations in product development

The SHIBAURA MACHINE Group is committed to the development of environmentally conscious products to offer our customers products with a lesser environmental load.

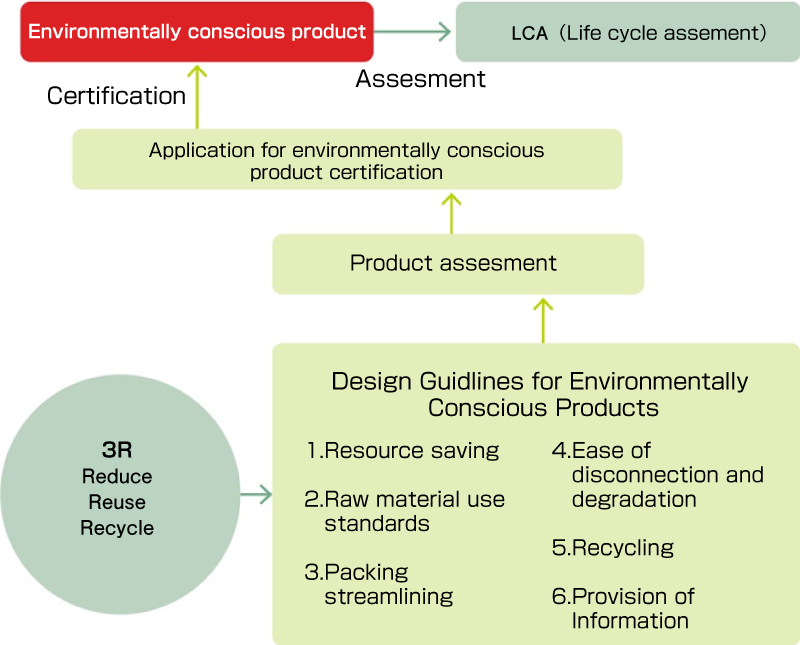

Developing environmentally conscious products

As early as the new product development phase, we perform "product assessments" to pre-estimate and reduce the product's potential impact on the environment. Engineering departments develop products pursuant to the "Design Guide for Environmentally Conscious Products", which incorporate design guidelines and 3R considerations.

When the development of a product is completed, an application for environmentally conscious product certification is filed for assessment, and if the product is certified, it is registered as an environmentally conscious product.

In fiscal 2023, 45 new models were registered, extending our environmentally conscious product list to 709 models.

Introduction of an environmentally conscious product

All-electric injection molding machine EC230SXⅢ S-Concept

TheAll-electric injection molding machine, "EC230SXⅢ S-Concept", requires 24% less power for heating than the conventional models, which has been achieved by improving the heat-retention performance through the review of the shape of the heater cover.

As a result, CO₂ emissions are reduced by 1.4 tons per year.

All-electric injection molding machine EC230SXⅢ S-Concept

Die casting machine DC850R2-M

With an improved hydraulic unit design and a more efficient pump, die casting machine DC850R2-M achieves the same performance with less energy compared to the existing R Series. As a result, DC850R2-M, which is a hydraulic clamping model, has achieved a 19% reduction in power consumption per cycle (35 seconds).

Die casting machine DC850R2-M

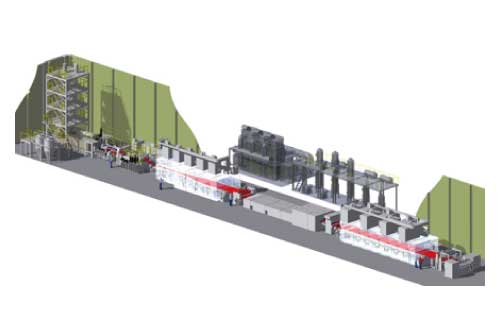

SFPU-55155XW Battery separator film manufacturing system for rechargeable batteries

Our battery separator film manufacturing device, "SFPU-55155XW", for secondary batteries for producing separator films, which are the materials for batteries, can manufacture films faster than the conventional ones. This supports further increase of the production of separator films, thereby contributing to a decarbonization of the society.

SFPU-55155XW Battery separator film manufacturing system for rechargeable batteries

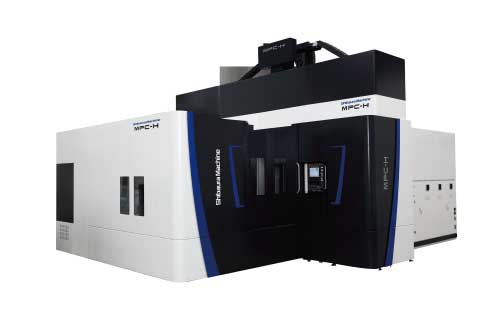

Double Column type Machining Center MPC-H series

In our MPC-H series of double column machining centers, we use environmentally-friendly paint that does not contain amine, which is hazardous to humans. Furthermore, we've cut the use of chemical substances subject to the PRTR system by 99% or more. We also do not use hazardous substances restricted by the RoHS directive. Normally, mist lubricant is used on main high speed rotary shafts, but the main shaft of this series of devices uses bearing grease, eliminating the need to use compressed air, as is necessary with mist lubricant. This reduces operation times for the compressors used to provide compressed air, further contributing to decarbonization.

Double Column type Machining Center MPC-H seriess

Scala Robot THE600

The amount of power consumption was reduced by 6% from that of the existing model by reducing the motor capacity from the existing model.

As a result, the amount of CO2 emitted at the manufacturing stage is to be reduced by 0.1t.

Scala Robot THE Series

Robot controller TS5000

While striving to further improve the control performance of our robots, we are reducing the number of heat sinks and circuit boards within the bodies of our devices, thereby making them more compact. We have achieved significant reductions in product weight (17 kg → 11 kg), helping conserve resources.

Robot controller TS5000