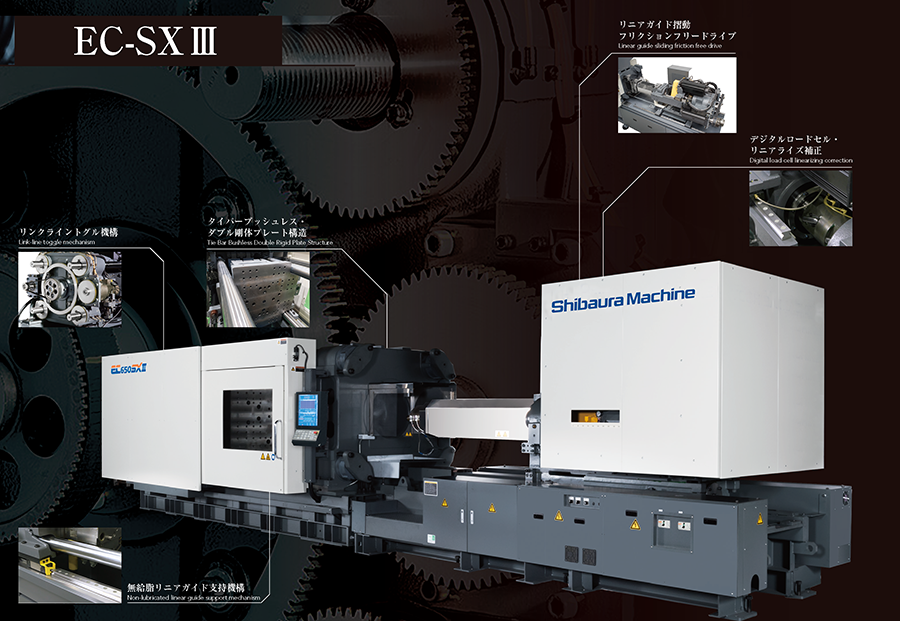

All Electric Injection Molding Machine EC-SXIII series

The EC-SXⅢ series is equipped with a new controller "INJECT VISOR-V70" that has dramatically improved functions from the conventional series, and it is possible to realize a smart factory by improving operability and visibility and connecting with a production control system. It has become. The medium and large class of the EC-SXⅢ series greatly contributes to productivity improvement by combining the mechanical performance and high-performance controller, which have significantly shortened the dry cycle and mold setup time from the conventional series. Furthermore, in order to evolve the popular high-precision core back, we have improved the die plate parallelism maintenance performance, making it a machine that can meet the back pressure accuracy requirements.

High quality

Endowed with the same high rigidity, high cycle, and high stability of former models, the new

series is equipped with a next generation HM i/f “INJECTVISOR V70” for high productivity and

easy operation in various production scenarios. It opens the way to a “connected factory.”

LINE UP

We have a rich lineup from small size (30 tons) to super large size (3000 tons).

※About 30 tons is EC30SXⅡ.

| Small | Medium | Large | Ultra large | ||||

|---|---|---|---|---|---|---|---|

| EC30SXⅡ※ | EC130SXⅢ | EC280SXⅢ | EC650SXⅢ | EC1300SXⅢ | EC1800SXⅢ | ||

| EC50SXⅢ | EC180SXⅢ | EC350SXⅢ | EC850SXⅢ | EC1300SXⅢW | EC2500SXⅢ | ||

| EC75SXⅢ | EC230SXⅢ | EC450SXⅢ | EC1000SXⅢ | EC1600SXⅢ | EC3000SXⅢ | ||

| EC100SXⅢ | EC550SXⅢ | EC1600SXⅢW | |||||

1. Mold clamping unit (Solid Clamp)

The device transforms uniform clamping force to the mold with newly designed toggle mechanism and improved rigidity, enabling molding by lower clamping force than conventional device. Moreover the device achieves high speed cycle of the industry-leading class.

- Toggle mechanism: link line toggle + two piece platens

・ Minimizes mold deflection and achieves uniform clamping force distribution.

・ Enables molding even by clamping force lower than conventional unit and contributes to improve product quality and mold maintenance reduction. - Dynamic acceleration/deceleration control (Patent pending)

・ Adopts acceleration/deceleration control to reduce shock at mold opening/closing.

・ Enables maximum accelerate from an arbitrary position achieving high speed cycle molding. - High response ejection

・Sharp movement shortens ejection time. - Grease-less tie rod

・Grease-less tie rods eliminates grease adhesion onto mold or product and maintains clean environment.

・ Standard rust proofing on the hopper inlet prevents mixing of rust or refuse into product. - SFC (high-speed mold open/close) specification (option)

・ Shortens dry cycle time further and achieves molding at higher speed cycle.

2. Injection Unit S-Cube (Simple ・ Steady ・ Smooth)

Takes over powerful filling performance in high speed and high pressure range and achieves steady molding by smooth movement.

- Friction-free drive

・Suppresses slide resistance to the utmost limit and contributes to precise and steady molding by stable injection characteristic.

・Smoothes leading response of injection and improves charging stability.

・Reduces variation among molding machines. - Control accuracy improvement in injection pressure and back pressure

- Absorbs inherent characteristic of pressure detector by linearize correction control, to lose machine difference to the utmost limit. This improves control accuracy of injection pressure and back pressure and achieves one up steady molding. - Ultra-high speed and high-pressure injection specification (option)

・ Achieves ultra high-response injection by a combination of newly developed low inertia /high response servomotor and direct drive mechanism.

3.Advanced Controller (INJECTVISOR V 70)

Shibaura Machine’s know-how in various molding solutions has been thoroughly incorporated into the unit to drastically improve customer productivity.

- High-Performance HMI (Human-Machine Interface)

・Equipped with two 19-inch resistive film type touch panels in top-bottom

configuration, icon menu legibility, ease of condition setting, and operation

customizing function. This is a controller with a high degree of setting flexibility to

meet the various needs of customers.

・Enables data browsing or printing on the personal computer by means of USB thumb drive or iPAQET LiTE.Process control tool "INDUSTROL" - Process Management Tools “INDUSTROL”

・“INDUSTROL,” a new function of the “INJECTVISOR V70” allows you to preconfigure and execute the die/molding conditions for the next process and process after the next process, as well as the die changing process for each die. This will drastically improve a customer’s production schedule control. - Signal customizing function

・Enables arbitrary selection of output signal to peripheral equipment.

・Allows each selection of output condition or output form. - Remote monitor/managerial system "iPAQET"

・Monitors and manages multiple molding machines in real time by using LAN line.

(Supports up to 100 units) - Plugin functions

・Enables plug-in of peripheral and rationalization equipments and facilitates integrated management including rationalization equipments.

4. Molding control (DST: Dynamic Self Tuning)

Automatic correction function is added to molding control. This contributes to reproducibility of high-precision molding and long-term steady molding.

- DST-Press (clamping force correction)

・ Does not generate sink mark or short shot (influence of gas vent) as a result of clamping force fluctuation.

・Automatic correction made during molding does not influence operation cycle while maintaining steady molding. - DST-Fill (molding condition correction)

・ Conducts automatic change of molding conditions and maintains steady molding, against the variation of molded product quality that takes place in a long period of operation as a result of resin lot change, crushed material ratio change or molding environment change. - Abundant molding controls

・A variety of function are installed, such as VHI (virtual hydraulic injection) circuit, high sensitivity mold protection and ejection torque monitor.

5. Screw variation

Screw variation matched to diversified resin types is available.

|

Screw name |

Resin |

|---|---|

| DBG Screw (Standard) | General purpose |

| SRB Screw | Engineering plastics |

| DBC Screw | Hard Vinyl Chloride |

| GN4 Screw | PMMA / Transparent Resin |

| BF Screw | BF screw intended to prevent generation of black spot is newly added. |

| EPS3K Screw | For Small Diameter PA / PBT |

6. Package specification

Satisfies customer's various needs.

- Thermosetting resin molding machine

- Vented-barrel injection molding machine

- Liquid silicone molding machine

- LCP spec/vinyl chloride spec/fluorine spec/connector spec/gas injection/light guide plate spec/MuCell spec

7. Moldable items (example)

Medical care

|

Molded article |

Material |

Moldable model |

Sample |

|---|---|---|---|

|

Connecting tube |

Multicolor |

50 ~ 130 tons |

|

| Syringe | PP | 100 ~ 280 tons |

|

|

Dialyzer |

PC / PP |

350 tons |

- |

General goods

| Molded article |

Material |

Moldable model |

Sample |

|---|---|---|---|

| Smartphone cover |

Multicolor multimaterial |

100 tons |

|

Food-related

|

Molded article |

Material |

Moldable model (Reference value) |

Sample |

|---|---|---|---|

| PET Preform | PET |

350 tons |

- |

Optical parts

| Molded article | Material | Moldable model (Reference value) |

Sample |

|---|---|---|---|

| Light guide component |

PMMA | 100 tons |

|

|

Light guide |

PMMA / PC |

130 ~ 450 tons |

- |

Automobile

| Molded article | Material | Moldable model (Reference value) |

Sample |

|---|---|---|---|

| Combiner Lens | PC / COP |

350 tons |

|

| Console box | PP / ABS |

350 ~ 550 tons |

|

|

Bumper |

PP |

2500 ton class |

- |

| Bumper *rear bumper spoiler |

PP | 1800 tons | - |