Environmental management

As the corporate social responsibility (CSR) based on our management philosophy and code of conduct, SHIBAURA MACHINE Group actively contributes to the development of a sustainable environment by being engaged in the compliance with laws and ordinances, provision of environmentally conscious products, and reduction of the environmental load associated with our business activities.

Strengthening the environmental management system

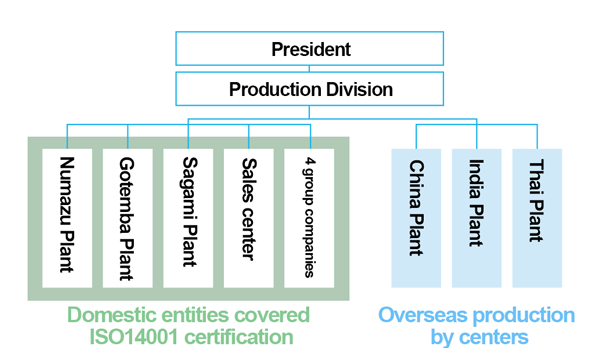

Since 1996, when we obtained ISO14001 certification for the Numazu Plant, we have been consolidating and enlarging the scope of certification to cover other production centers, sales centers, and group companies in Japan in the effort to facilitate concerted efforts across the group and strengthen its environ- mental management struc- ture. Speaking of overseas operations, we obt ained certification for the Shanghai plant in 2004, for the Indian plant in 2012 , and for the Thailand plant in 2015.

In fiscal 2017, we completed document revisions to reflect ISO14001:2015.

ISO 14001 certification acquired

Making productive use of environmental management

SHIBAURA MACHINE Group has established and is implementing an “Environment Manual”, which describes the ISO requirements in detail, down to the operation level. We also continuously participate in the “Toothbrush Recycling Program”, as a part of the campaign for recycling used toothbrushes. In addition, having approved the “Kanagawa Zero Waste Declaration”, which is tackled by Kanagawa Prefecture, our Sagami Factory is continuously engaged in the program. We will continuously promote the environmental activities along with the business activities by effectively utilizing the environment management system.

Compliance with environmental laws and responses to environmental accidents and complaints

At each production site, we try to prevent environmental accidents caused by the discharge of harmful substances into the atmosphere and water areas by establishing the voluntary control standard values more strictly than those set out by the Law. We also ensure the proper implementation of notification, reporting, and standard compliance at the internal auditing as well as verifying the management statuses of the environmental facilities by monitoring them. The trends of laws and regulations are shared within the Group. In 2024, we disseminated the information on the law, "Act on Rationalizing Energy Use", a version amended by expanding further the definition of the Energy Conservation Act. As a result, no complaints were received from neighbouring residents of the Group in FY2024.

Environmental internal auditing

An auditing team was established in each company/center to conduct internal environmental auditing in the form of mutual auditing. Recruitment and skill enhancement of internal auditors are also promoted by providing education for internal auditors. In the FY2024, 15 cases were pointed out including improvement guidance. We are promoting systems for producing environmental results and enhancing the management of environment-related facilities.

Environmental education and training (domestic)

Education and training corresponding to the level and profession are provided.

By providing the environment education (e-learning) course, we promote the enhancement of environmental awareness.

In addition, each department conducts drills to cope with emergency situations, such as the leakage of a pollutant from a plant.

Acquisition of environment-related certifications

At each site, we are engaged in systematic acquisition of applicable certifications to respond to the environment related laws and regulations and local bylaws and improve the management level.Since FY2023, we have been encouraging employees to obtain sustainability certifications.