Pollution control initiatives

Environmental Measurement and Analysis at Shibaura Machine Group

The SHIBAURA MACHINE Group engages affiliated company SHIBAURA SEMTEK Co., Ltd. for the measurement and analysis of pollutants discharged from its plants. The data is gathered and constantly analyzed. These results are used to reduce environmental load and prevent pollution.

We have technical specialists who perform environmental measurement and material analysis for water and air quality, and working environments at business divisions, and furnish information necessary for environment and quality maintenance and improvement. We also offer environment-related equipment for sale and are working toward protecting the rich environment as an excellent support partner.

Measuring / inspecting process

Reduction of PRTR substances with a change to new paints used for machine tools

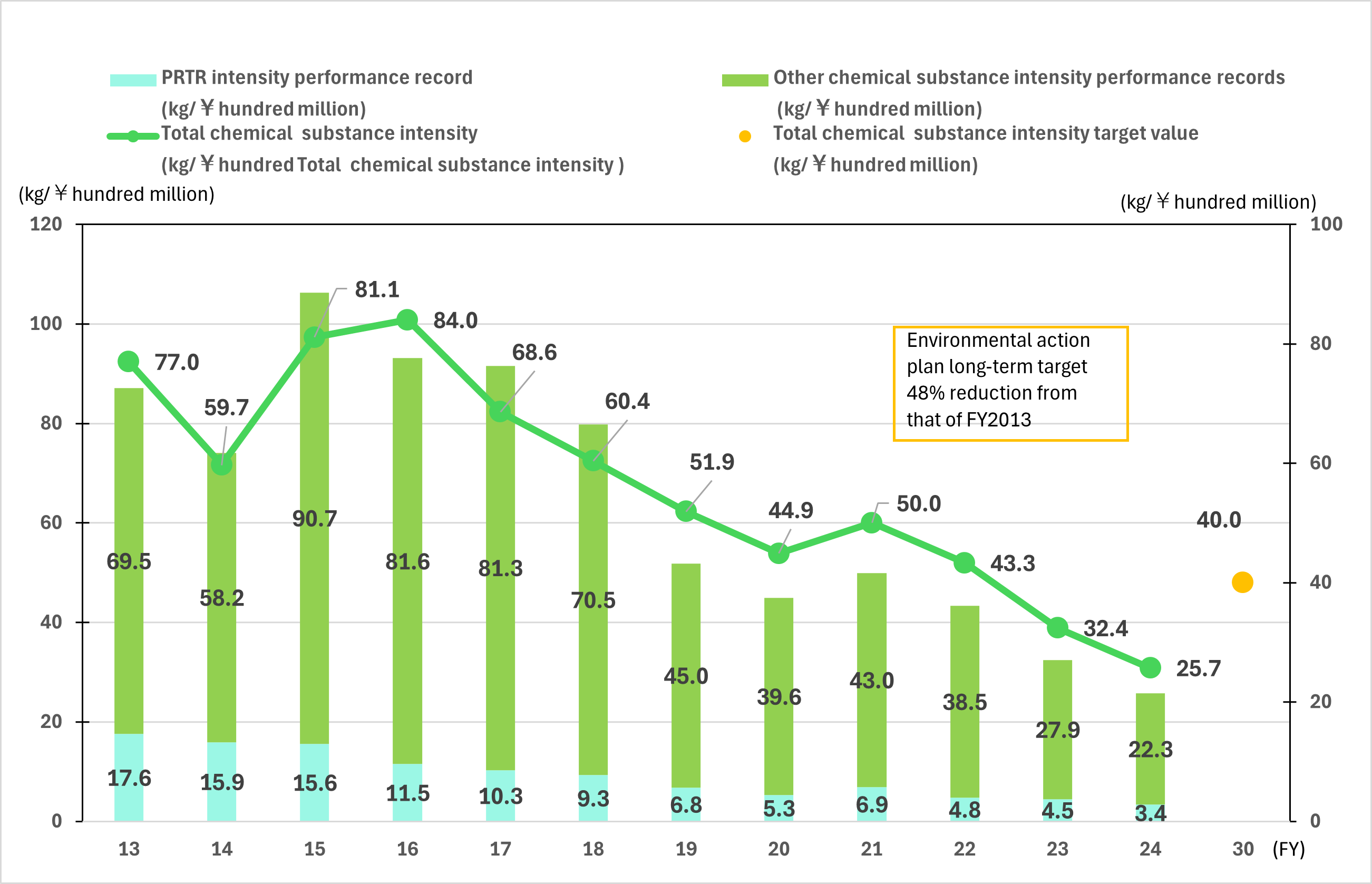

Since FY2006, the Shibaura Machine Group has been working to reduce PRTR substances. Major initiatives for this purpose include changing paints and improving solvent use efficiency in the painting process. As a results, we reduced emissions by 71% in FY2024 compared to FY2013.

Starting in FY2022, we changed paints used for machine tool products to those with lower toluene content. We also use diluents with no toluene and xylene content to help reduce PRTR substances.

Air pollutants

The discharged amount of air pollutants, including soot and dust, nitrogen oxide, and sulfur oxide, remained almost unchanged. Energy-saving activities are continued at each production center, and discharge standards and agreed thresholds are met for all specified facilities, such as casting smelting furnaces and boilers at the Numazu, Sagami, and Gotemba Plants.

Water pollutants

The discharged amount of water pollutants remained almost unchanged.Discharge standards and agreed thresholds are met for the Numazu, Sagami and Gotemba Plants and the production facilities of Fuji Seiki Machine Works, Ltd.

VOC discharge

The painting facilities of the Numazu Plant are subject to VOC regulations and have met the discharge standards and the values reported to Numazu City.

We also established a cooperation and communication structure in accordance with Shizuoka Prefecture's guidelines on the handling of photochemical oxidant emergencies.

Storage and disposal of waste electrical equipment containing PCB

We request disposal of waste electrical equipment containing a high PCB concentration to a specialized waste service company as required and at the same time, are continuously checking for any PCB residues within the factories.

Waste electrical equipment of low PCB concentration is also disposed of in the same way as required.

Actions to reduce noise, vibration, and offensive odors

The noise and vibration standards of the group companies and plants are met at all the designated places at all the designated times of the day. We confirmed offensive odor standards are met at all the designated border points of the plants.

Actions to control soil and groundwater pollution

In preparation for dismantling some of our Numazu Plant buildings in Numazu City, Shizuoka Prefecture, we conducted a voluntary soil survey at the building site. The survey indicated that specified hazardous substances were present at some of the land lots in concentrations exceeding the thresholds under the Soil Contamination Countermeasures Act. We reported these survey results to the Numazu City government and filed area designation applications as specified by the Soil Contamination Countermeasures Act. We will take appropriate measures in accordance with guidance from the Numazu City government when performing work involving land excavation at the land lots designated as areas subject to notification for land alteration.

Management of chemical substances

The PRTR substances reduction target for FY2030 in our 1st environmental action plan was achieved in FY2019; therefore, we changed the long-term reduction target for FY2030 from 30% to 48%. This target was achieved in FY2023, and future targets are under review.

Chemical substance discharge amounts, intensity performance records, and targets