Engineering and services

SHIBAURA MACHINE Group offers systems and services that can satisfy customers worldwide based on our management philosophy.

R&D Center that explores the possibilities of new technologies and businesses

The R&D Center is a new site that creates cutting-edge products of Shibaura Machine. By capturing the future vision of the society and SHIBAURA MACHINE from the long-term viewpoint, we create new businesses and industries through the research not restricted to the existing business domain and development of new technologies and at the same time realize sustainable development and social contribution towards the future, which can be in 10 years’ time, 20 years’ time, or further ahead.

Future vision plotted by SHIBAURA DX

We are working to utilize digital technology and AI based by building on our technical and product capabilities, aiming to realize technological innovation especially in "Energy," "Automobiles," and "Social Patterns." At the same time, it is Shibaura Machine's mission to enhance labor productivity and pursue efficient and sustainable manufacturing using less energy, both of which directly contribute to the achievement of the SDGs, and to provide these solutions to society. We will further evolve the technologies we have developed over the years and create those that offer value for the next generation by focusing on strengthening fundamental technologies and driving innovation in new technological areas under the leadership of the R&D Center. We will continue to meet our customers' expectations and remain committed to creating a sustainable, competitive future.

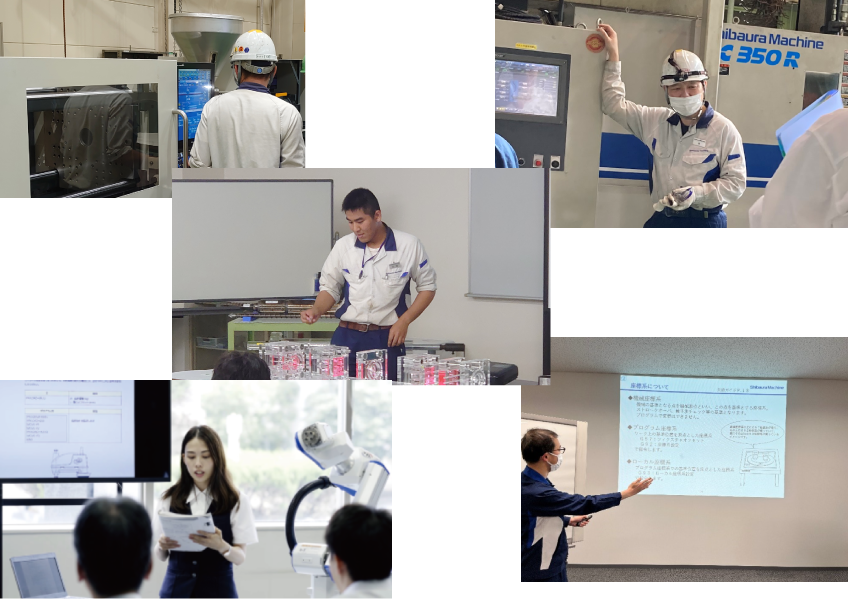

Voices of students of various schools

We have prepared various schools for the customers who purchased SHIBAURA MACHINE products according to the experience, level, and purpose.

■Injection molding machine【IS school】

- I had seen molding machines at the company before, but it was great to actually experience and learn things I never knew, such as the data shown on the monitor and the sequence of steps for setting the mold.

- Through this training, I was able to learn terminology and defect-prevention measures that I hadn't fully understood before. It was a very worthwhile experience.

- I learned that some aspects of automatic purging were different from my understanding, so I am glad I could get clarity on this. Since everyone has their own methods for color changes, I want to take back what I learned in this training and share it with my workplace. Some of the techniques I have learned in this training appear effective for addressing defects we’re currently seeing in our company, so I’d like to try them out.

■Die casting machine【DC school】

- The training materials were closely related to my work and I found it very beneficial.

- The instructor explained the theories in an easy-to-understand manner, using real-life examples to help us understand them thoroughly.

■Machine tool【NC school】

- Thorough explanations on each process gave me a deeper understanding. I will use the knowledge I gained from the training with my job.

- This is the first time I learned machine process programming and operation on a real machine. The thorough training provided the understanding of the subject even for me who has no prior knowledge on this subject. I am pleased to have received the training from the NC School.

■Industrial robot【Robot school】

- The small-group lesson allowed me to have practical exercises based on the real work in the afternoon session of the second day, providing satisfactory contents.

- Although I have never used a robot of Shibaura Machine before, the two-day training program starting from the basics of the applications gave me a confidence of the handling of start-up after installation.

- As the contents of the lesson were so structured that they are similar to the operations of the actual system, it was very useful. The exhibition of the robots other than those that were used was also helpful for reference.

EX Academy (Extrusion machines) opened

Shibaura Machine, which is a pioneer of extrusion machines, has responded to all sorts of customer requirements. For the coming 70th anniversary since the development of a twin-screw extruder in 1955, we took this opportunity to establish the EX Academy (TEM School and SPU School) to provide the training for the optimum use of the extrusion machines.

We opened a TEM School for twin-screw extruders first and in June 2024, we also opened a SPU School for sheet manufacturing devices according to the requests from customers.