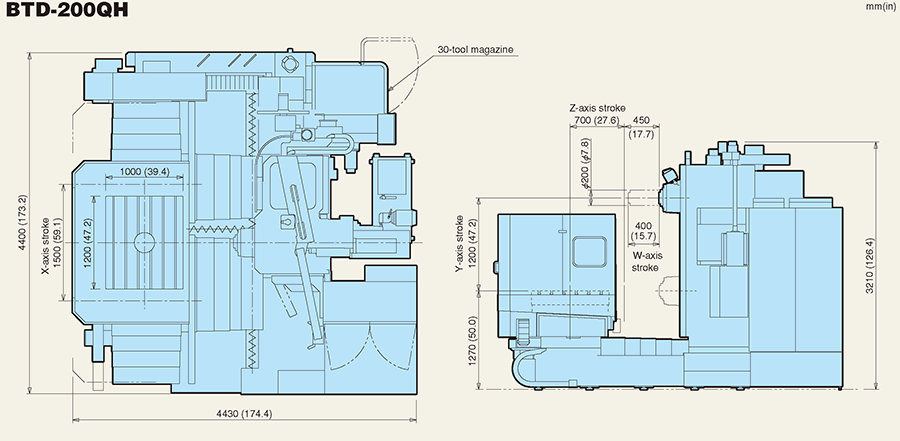

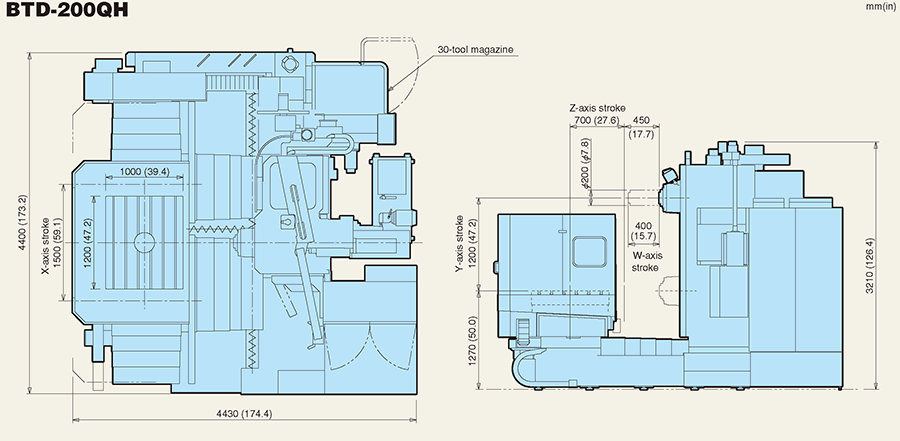

BTD-200QH

Highly Preferred FLEXMACHINE. Supported by many users from generation to generation Easy-to-use and equipped with new features supporting more advanced machining operations

Main features

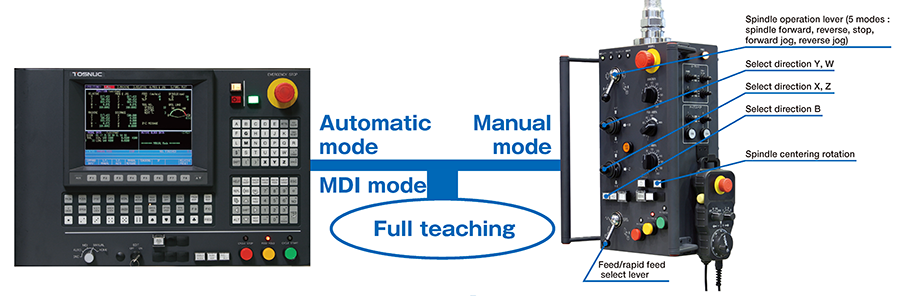

Easy-to-operate compact pendant for manual machining operations

Most sophisticated CNC system TOSNUC 999

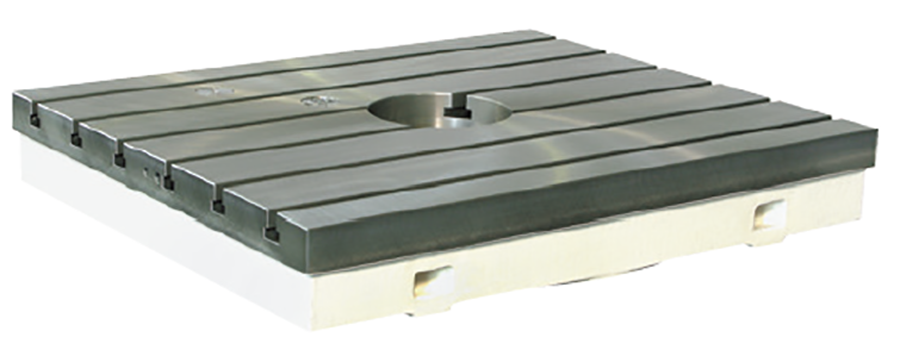

Wide table withstand heavy load and allows easy se

The table as wide as 1000 x 1200mm has a standard maximum load mass of 4 tons. Thus, enabling the set-up of work-pieces with longer widths.

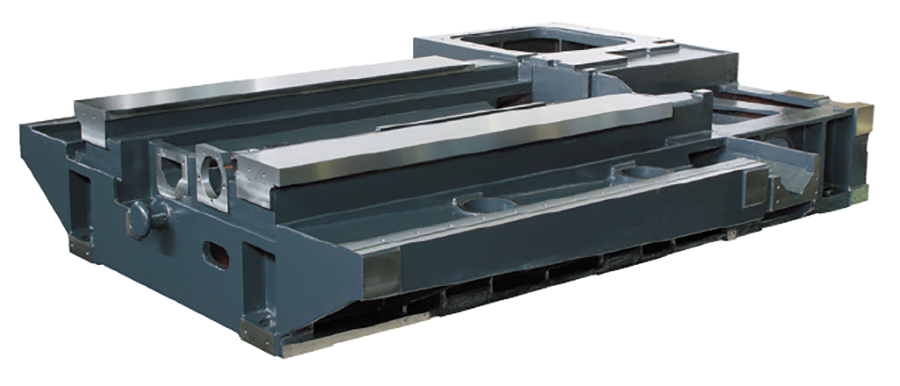

High rigidity bed supports the entire machine

The new integrated type 4-way structure bed minimizes influences of load fluctuations caused by the movements of saddle and table, and maintains machining accuracy even at heavy-duty cutting operation

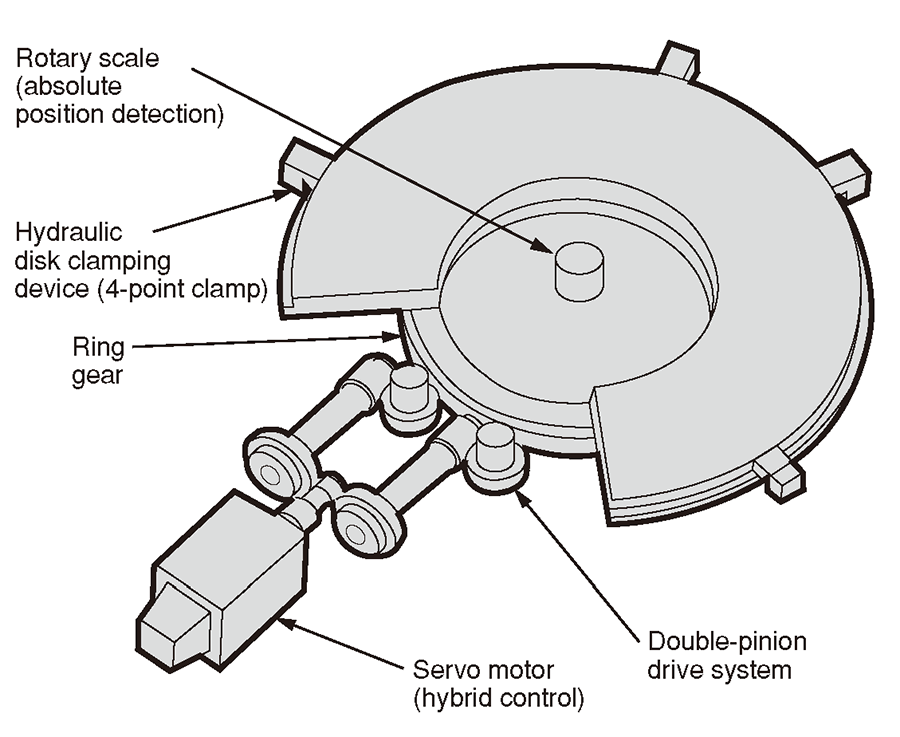

B-axis drive mechanism provides high-speed and high-accuracy machining

Use of the highly rigid double-pinion drive system and standard rotary scale emphasizes stable high-speed and high-accuracy table indexing operation

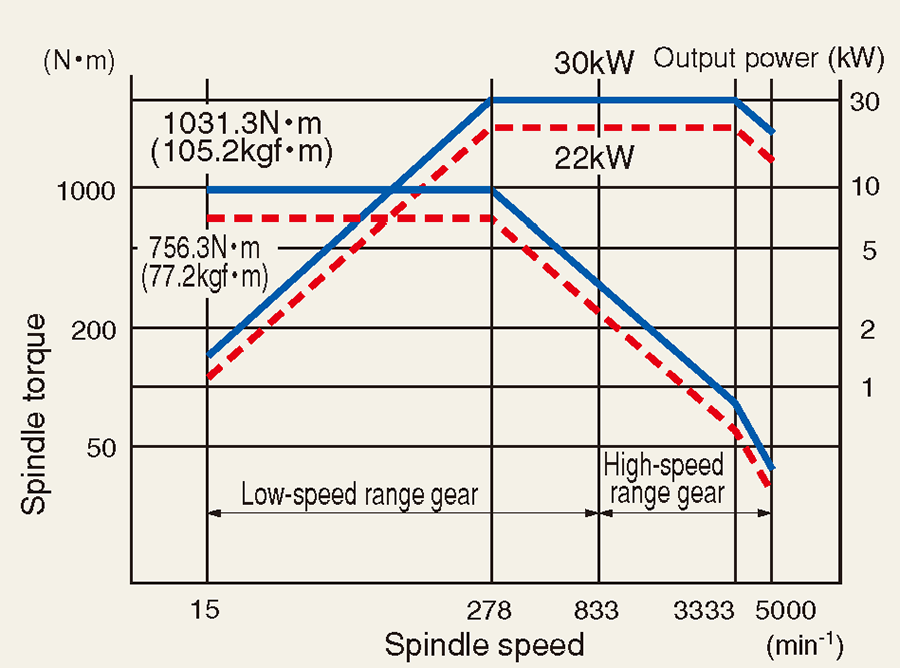

5000min-1 spindle with high-speed and high-torque specifications (option)

The mechanical two-stage gear change system with high-speed and high-torque 5000 min-1 spindle can cope with more extensive machining operations, exceeding the current high-rigidity quill structure

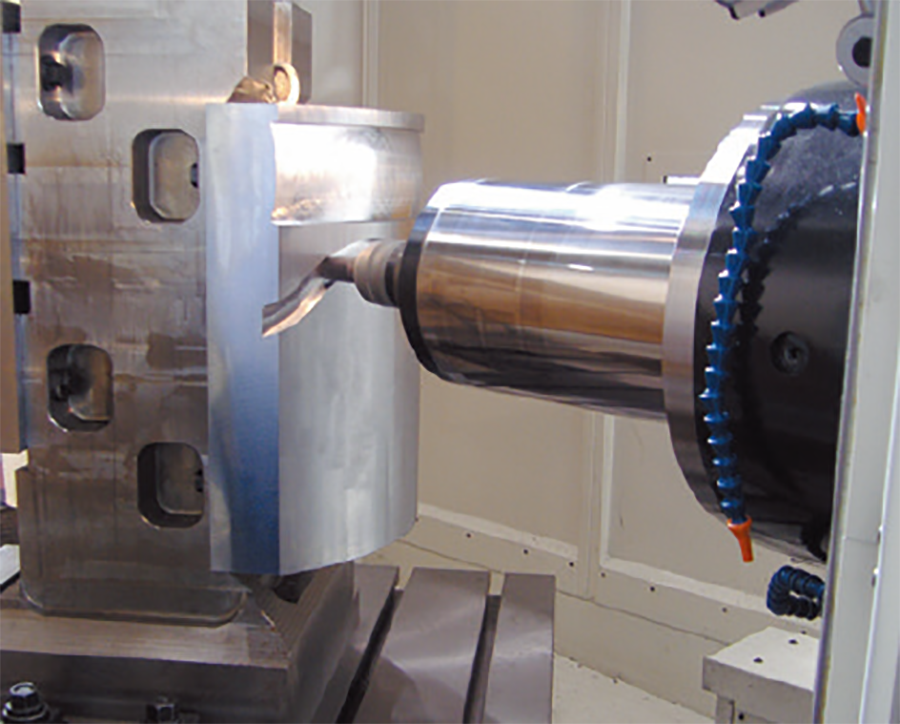

NC rotary milling operation (option)

A cylindrical surface and end surface can be machined continuously by using the B-axis continuous indexing function of the table without using a special independent NC rotary table Easily

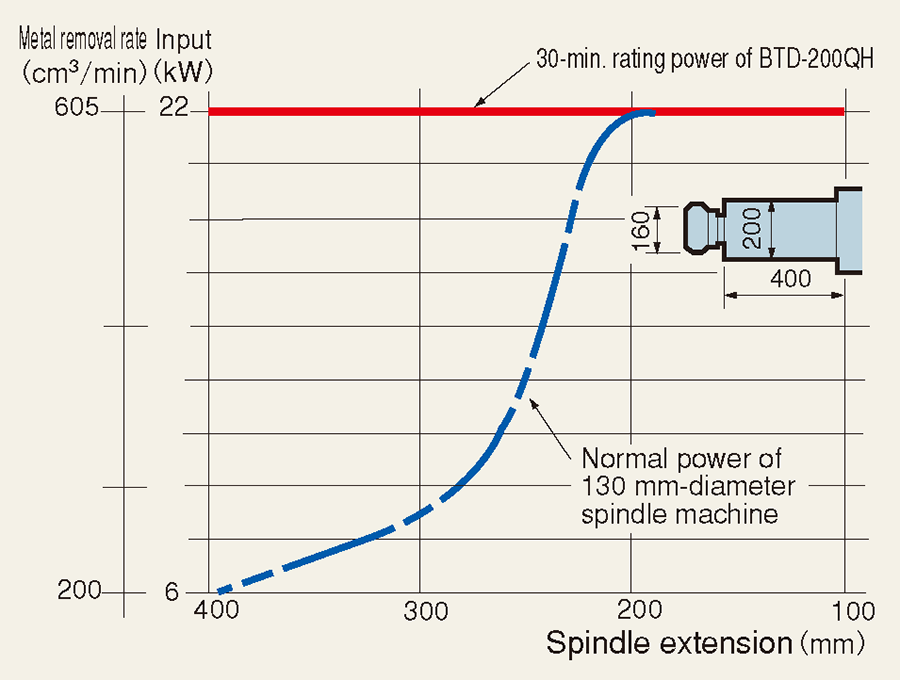

Fully extended 200 mm-diameter quill Spindle capable of powerful cutting type shown at 400 mm maximum. with quill extended at 400 mm.

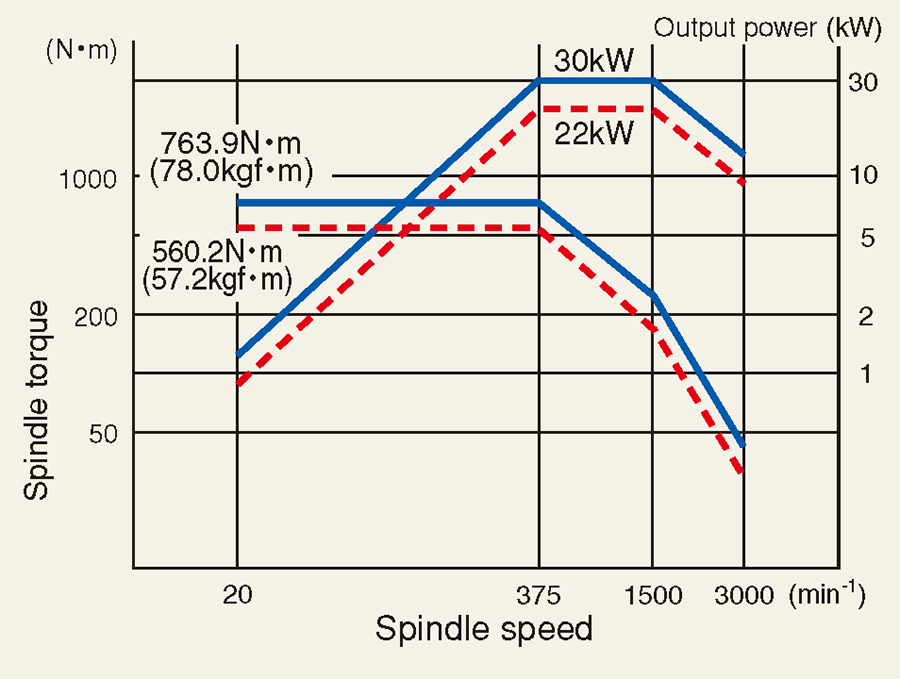

Spindle torque/output power diagram (standard specification) 3000min-1

Spindle torque/output power diagram (Option) 5000min-1

Face milling ability (workpiece material: AISI 1055)

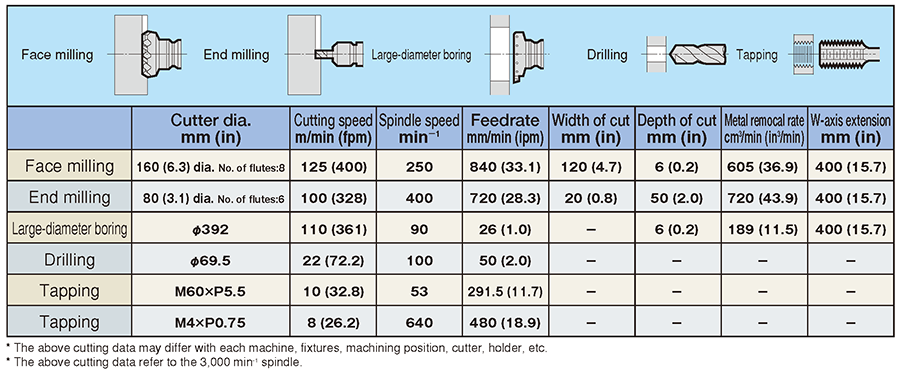

An example of cutting ability (workpiece material: AISI 1055)

Wide table withstand heavy load and allows easy set-up.

The table as wide as 1000 × 1200 mm has a standard maximum load mass of 4 tons. Thus, enabling the set-up of work-pieces with longer widths.

B-axis drive mechanism provides highspeed and high-accuracy machining.

Use of the highly rigid double-pinion drive system and standard rotary scale emphasizes stable high-speed and high-accuracy table indexing operations.

High rigidity bed supports the entire machine.

The new integrated type 4-way structure bed minimizes influences of load fluctuations caused by the movements of saddle and table, and maintains machining accuracy even at heavy-duty cutting operations.

NC rotary milling operation (option)

A cylindrical surface and end surface can be machined continuously by using the B-axis continuous indexing function of the table without using a special independent NC rotary table. Easily create an NC program for the cylindrical surface using the cylindrical interpolation function (G67).

5000 min-1 spindle with high-speed and high-torque specifications (option)

The mechanical two-stage gear change system with high-speed and high-torque 5000 min-1 spindle can cope with more extensive machining operations, exceeding the current high-rigidity quill structure.

TOSNUC999

TOSNUC999 (Triple nine) permits quick switching between manual, MDI and Automatic operation modes.

Customizing keys

1.Memorize a series of input operations beforehand in one of the special keys and press these keys to execute operations continuously.

2.Memorize a combination of NC standard displays such as main, sub and window displays in one of the special keys. By pressing these keys it displays the combination memorized.

Supporting both USB memory and compact flash (CF)

A compact flash (CF) slot is standard-equipped to cope with large-capacity NC programs.

Full screen program editing function helps create an NC program easily.

-

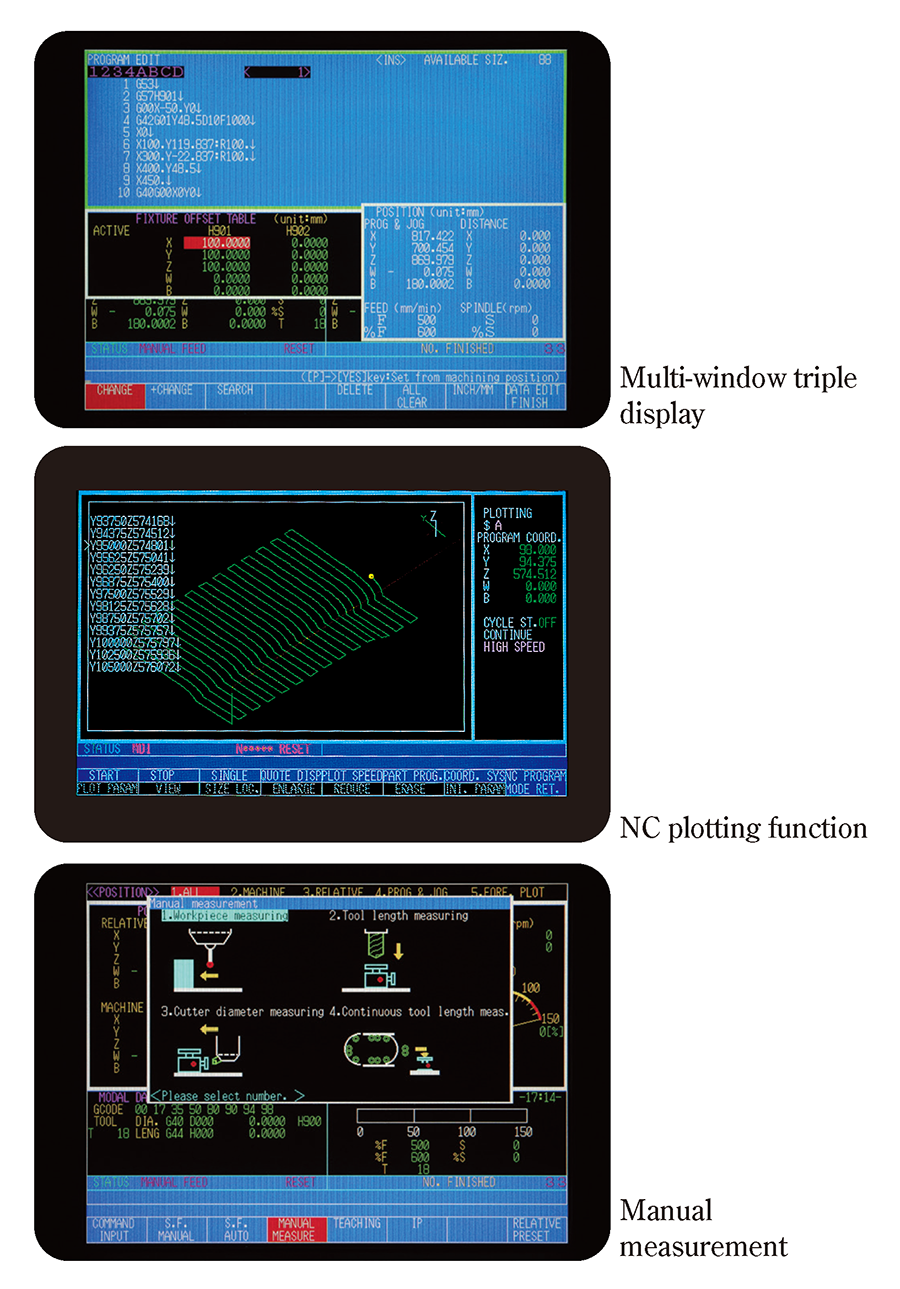

Multi-window triple display

The display of TOSNUC 999 can be divided into three separate screens where simultaneous display of two different programs and offset data necessary for machining is possible. Also, data entry and editing can be done separately on each screen. -

Multi-editing function

A new program can be easily created by referring to and utilizing a previously made program on the multi-window display.

Visual program check function (option)

During programmed operation (i.e., background operation), an NC tape image of another program can be checked graphically. After program check, relevant tool path is drawn.

Triple teaching function for simultaneous machining and NC programming (option)

TOSNUC 999 stores in its memory all data created by the operator as NC programs. Programming is very easy by combining these programs, using various teaching functions.

-

Manual teaching function

All machining data such as tool path, spindle speed and feedrate as obtained in the manual mode are stored automatically as an NC program. -

MDI teaching function

When machining processes are executed one by one consecutively in the MDI mode, all such data are stored automatically as an NC program. -

Auto teaching function

In the AUTO or DNC mode, any data which has been modified can be fed back to the memory automatically.

Various functions shown above significantly improve operability

-

Manual alignment (centering) function

The touch sensor or master tool comes into contact with the measured surface of a workpiece according to the interactive screen, inner and outer diameters and angle of inclination of the specific workpiece that automatically calculates set-up.

Main machine specifications (standard)

|

|

|

Standard | with APC | ||

| Travel | X–axis travel (Cross movement of table) | mm[in] | 1 500(59) | ||

| Y–axis travel (Vertical movement of spindle head) | mm[in] | 1 200 (47.2) |

1 000 (39.3) |

||

| Z–axis travel (Longitudinal movement of table) | mm[in] | 700(27.5) | |||

| W-axis travel (Quill extension) | mm[in] | 700(15.7) | |||

| Distance from table surface to spindle centerline | mm[in] | 0~1 200 (0~47.2) |

0~1 000 (0~39.3) |

||

| Distance from table centerline to spindle gage plane | mm[in] | 450~1 150(17.7~45.2) | |||

| Table | Table working surface | mm[in] | 1 000~1 200(39.3~47.2) | ||

| Table loading capacity | kg[lb] | 4 000 (8 800) |

3 500 (7 700) |

||

| Table surface configuration (Pitch of T-slots: 160 ㎜) |

mm[in] | 6 T-slots, size 22 ,pitch 160 (size 0.86, pitch 6.2) |

|||

| Minimum table indexing angle | deg | 0.0001° | |||

| Spindle | Rotating spindle diameter | mm[in] | 110(4.33) | ||

| Extended quill diameter | mm[in] | 200(7.8) | |||

| Spindle speed | min-1 | 20~3 000[15~5 000] | |||

| Number of spindle speed ranges | 1 range[2 ranges] | ||||

| Type of spindle taper hole | 7/24 taper No.50 | ||||

| Spindle bearing inner diameter | mm[in] | 110(4.9) | |||

| Feedrate | Rapid traverse rate | X,Y,Z | m/min[ipm] | 12 0000(472.4) | |

| W | m/min[ipm] | 5 000(196.8) | |||

| B | deg/min | 1 080 | |||

| Feedrate | X,Y,Z | mm/min[ipm] | 1~6 000(0.039~236.2) | ||

| Automatic tool changer | Type of tool shank | MAS BT50 | |||

| Type of retention knob | MAS P50T-1(45degree) | ||||

| Tool storage capacity | 30 [60, 90] | ||||

| Maximum tool diameter | When pots are full | mm[in] | 125(4.92) | ||

| When adjacent pots are empty | mm[in] | 240(9.44) | |||

| Maximum tool length | mm[in] | 400(15.74) | |||

| Maximum tool mass | kg[lbs] | 25(55) | |||

| Tool selection | Pot address random short-cut | ||||

| Spindle drive Motor | (30-min. rating/cont. rating) | kW[HP] | AC30/22(AC40/30) | ||

| Power sources | Electric Power supply | AC200/220±10%, 50/60Hz±2% | |||

| Power capacity | kVA | 68 | 72 | ||

| Compressed air supply | Pressure | Mpa{kgf/cm2}(psi) | 0.5~0.8{5~8}(82.5~116) | ||

| Flowrate | N/min | 150 | |||

| Machine size | Machine height | mm[in] | 3 210(126.4) | ||

| Floor space | mm[in] | 4 400×4 430(173.2×174.4) | 4 870×6 690(191.7×263.4) | ||

| Mass of machine (including CNC systems) | kg[lbs] | 18 000 (39 600) |

23 000 (50 600) |

||

| Accuracy | Positioning accuracy | X,Y,Z | mm[in] | ±0.005/full length (±0.00019/full length) |

|

| X,Y,Z (with scale) |

mm[in] | ±0.003/full length (±0.00011/full length) |

|||

| W | mm[in] | ±0.012/full length (±0.00047/full length) |

|||

| Repeatability | X,Y,Z | mm[in] | ±0.003 (±0.00011) |

||

| X,Y,Z (with scale) |

mm[in] | ±0.002 (±0.00007) |

|||

| W | mm[in] | ±0.008 (±0.00031) |

|||

| Table indexing accuracy (arbitrary angle) | ±3″ | ||||

| Table indexing repeatability(arbitrary angle) | ±1.5″ | ||||

| Exterior painting color | R4-383(Munsell Y8.4/0.5)andN2.5 (For CNC system, servo motors and cooler, each maker's standard color shall apply.) |

||||

Note:Values in brackets [ ] refer to the options.

The values in the specifications table above indicate the maximum capacity. If a continuous long-hour operation is required at the maximum capacity, please consult with us beforehand.

Machine Extemal View

Machine External View

Table Top View

Standard accessories

| 1 | Numerical control system TOSNUC 999 | 1 set |

| 2 | Machine operation box (pendant type) | 1 set |

| 3 | Automatic quill clamping unit | 1 set |

| 4 | Spindle orientation stop function | 1 set |

| 5 | Spindle speed drop monitoring function | 1 set |

| 6 | Handwheel feed unit for X-, Y-, Z-, W-, B-axes (portable) | 1 set |

| 7 | Incremental 0.0001° automatic table indexing unit (with rotary scale) | 1 set |

| 8 | Automatic (hydraulic) table clamping unit | 1 set |

| 9 | Table oil pan | 1 set |

| 10 | Saddle slideway cover | 1 set |

| 11 | Bed slideway cover | 1 set |

| 12 | Column front cover | 1 set |

| 13 | Work light (spot light) | 1 set |

| 14 | Assembly and disassembly tools for maintenance | 1 set |

| 15 | Installation parts | 1 set |

| 16 | Automatic main power OFF unit | 1 set |

| 17 | Plug receptacle for external equipment (AC100V, 5A) | 1 set |

| 18 | Hydraulic unit with oil cooler |

|

Available options

CNC System Specifications TOSNUC 999

Standard Specifications

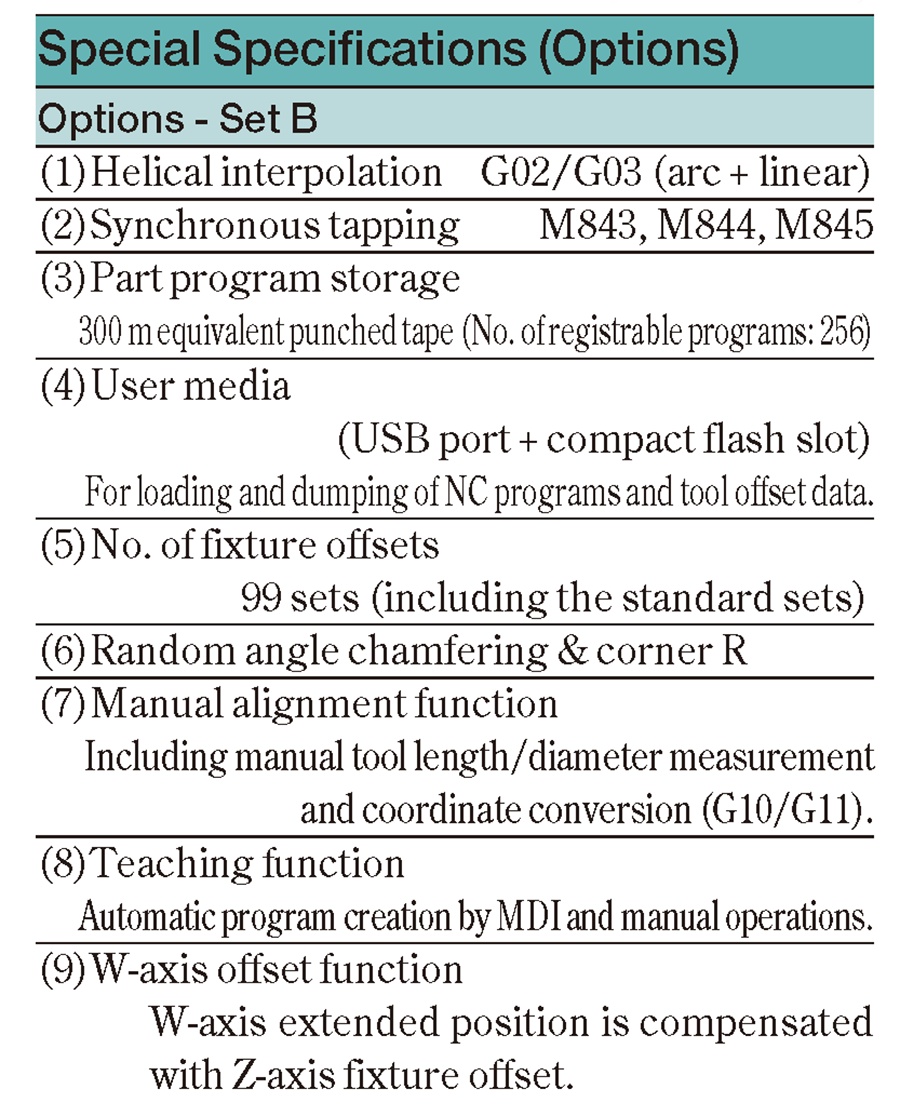

Special Specifications (Options)

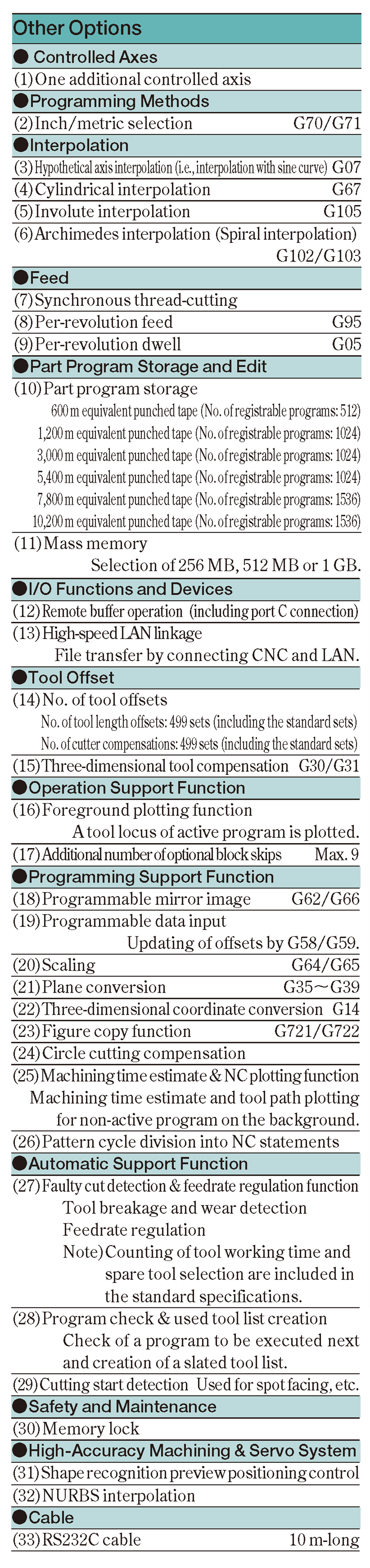

Other Options

CNC system TOSNUC999

CNC system Sorcifications(PDF/1.9MB)

User media (option set B)

Very useful device for managing long programs.

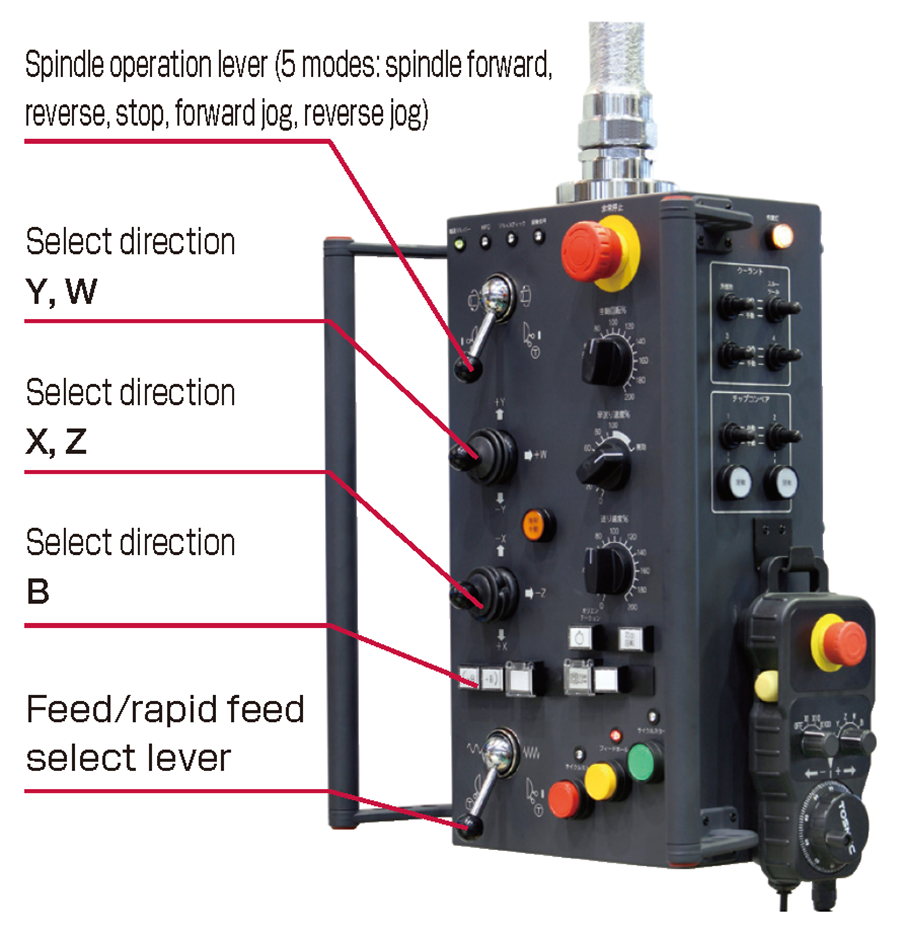

Pendant operation box

Manual operations relating to machine movements are separated from the NC operation unit and centrally arranged on the pendant operation box. Thus, combined NC and manual machining operations can be performed smoothly.