Die Casting Machine Total Control System

TOSCAST-999 / 888

TOSCAST-999 / 888

HMI | Quality Items | Injection Waveform | Password Function | PLC ladder | Operation monitor

All R series models are equipped with the

new control unit TOSCAST-888 as standard.

new control unit TOSCAST-888 as standard.

With the human interface based on ergonomics,

The large 15-inch screen improves the operator's maintenance and management environment.

The system is multilingual with input control management, which also improves the efficiency of global production management.

In addition, Shibaura Machine's proprietary failure diagnosis function is standard, and dPAQET (optional),

and Remote maintenance function (optional) contributes to improved maintainability and production efficiency.

Well-designed HMI (Human Machine Interface)

Integrate a well-designed GUI (Graphical User Interface) based on ergonomics.

The large 15-inch touch panel also improves operability.

48 quality items

The number of quality control items increased to 48.

The increased number of items enables quality control from various perspectives,

such as temperature and each process time, in addition to conventional items.

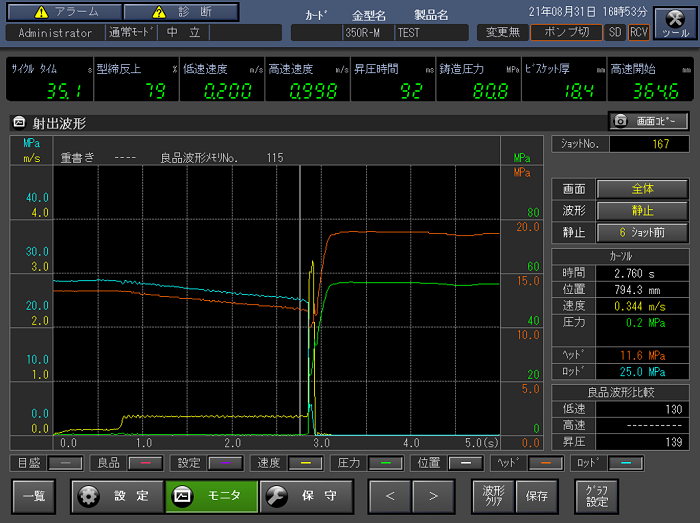

Number of injection waveforms increased

In addition to injection position, injection speed, and casting pressure, the number of options such as vacuum has been added from one to two.

In addition, TOSCAST-888 can support up to 6 optional waveforms.

Password (user management) function

Passwords can now be used to prevent changes to conditions during production and to restrict operations by user.

Set conditions, monitor, and maintenance on a per-screen basis.

PLC Ladder Online Monitoring

PLC ladder can be monitored online.

This can be useful for investigating the cause of malfunctions and troubles.

Improved Operation Monitor

The operation monitor has easier viewing.

The display size and design changed to check the machine status easier.