Test equipment introduction

Our test equipment has a lineup of 120 mm, 400 mm, and 200 mm for double-sided transfer. We will provide tests according to your specifications.

Verification details in test equipment

・Optimizing coating depth, nip amount, nip pressure

・Film base handling tension control, line speed

・Matching of the film base and UV-curable resin

・Molding shape evaluation

・selection of UV-curable resin etc.

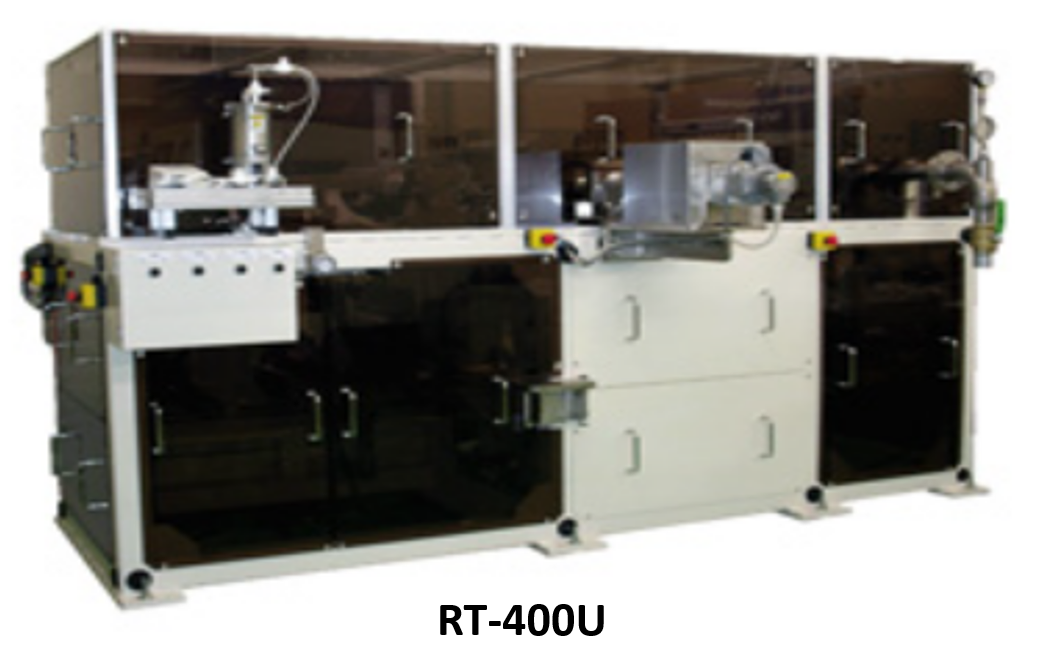

Roll-to-roll type UV transfer device test machine schematic specifications

| RT-120U |

RT-120U |

RT-200WU (Double-sided transfer) |

RT-400U | ||

|---|---|---|---|---|---|

| Feed rate | 0.1 ~ 3.9 m/min | 0.1 ~ 3.9 m/min | 0.1 ~ 9 m/min | 0.5 ~ 30 m/min | |

|

Coating width |

60 ~ 80 mm | 60 ~ 80 mm | 80 mm | 100 ~ 240 mm | |

| Mold | Material | Ni Stamper・Resin mold | Transparent resin mold | Resin mold | Ni Stamper・Resin mold |

| Thickness | 0.2 mm Less than | 0.2 mm Less than | 0.2 mm Less than | 0.2 mm Less than | |

| width | 100 mm Less than | 100 mm Less than | 200mm Les than | 350mm Less than | |

| length | 620 mm Less than | 620 mm Less than | 314 mm Less than | 780 mm Less than | |

| Base film | Material | Opacity film |

Transparent,opaque film |

Opacity film | Opacity film |

| (Easy adhesion type ) | (Double-sided easy-adhesion type ) | (Easy adhesion type ) | |||

| core | Φ 3 inch | Φ 3 inch | Φ 3 inch | Φ 3 inch | |

| Thickness | 50 ~ 188 µm | 50 ~ 188 µm | 50 ~ 188 µm | 50 ~ 188 µm | |

| width | 100mm Less than | 100mm Less than | 180mm Less than | 300mm Less than | |

|

Roll diameter |

Φ 200 mm | Φ 200 mm | Φ 200 mm | Φ 300 mm | |

| UV-resin | Clay | 5 ~ 60 mPa・s | 5 ~ 60 mPa・s | 5 ~ 60 mPa・s | 5 ~ 2000mPa・s |

| UV Lamp | Metal halide lamp UV-LED 385nm |

UV-LED 365nm | UV-LED 385nm | Electrodeless lamp Metal halide lamp) | |