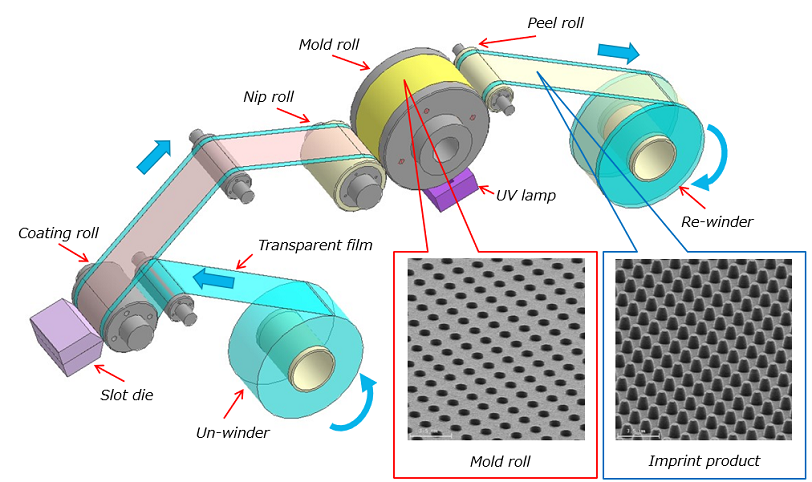

Machine configuration

1.The transparent film is fed out from the feeding shaft and coated with UV curable resin.

2.The film is pressed through the nip roll onto a roll-shaped mold called a mold roll to transfer the shape of the mold roll.

3.The resin is hardened by UV irradiation, and the process from mold release to winding is performed in a continuous process and create a molded product.

Custom support is available for the requests for wider width, higher speed, protective film bonding, resin mold support, etc.

| Item | RT-120U | RT-250U | RT-400U | RT-800U |

|---|---|---|---|---|

| Roll width | 120mm | 250mm | 400mm | 800mm |

| Imprint roll dia | φ200mm | φ200mm | φ250mm | φ250mm |

| Film width | 100mm | 230mm | 350mm | 700mm |

| Coating width | 80mm | 190mm | 300mm | 650mm |