Introduction of Shibaura Machine's horizontal machines.

This is an introduction and guide to the standard specifications of the table type horizontal boring milling machine, horizontal machining center, and floor type horizontal boring milling machine.

We have a rich lineup to choose from according to the target workpiece and spindle diameter.

Please feel free to inquire about details and special accessories.

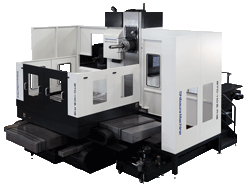

Table-Type Horizontal Boring and Milling Machine

BTD series

Table Traverse

Standard type with table traverse in Z-axis

Introducing a new design!

Approachability and strong spindle are the strengths.

The best-selling machine has evolved into a high-performance, high-productivity machine, supported by many users

CNC controller can be selected between TOSNUC and FANUC.

Standard specifications

size:【BTD - 〇〇〇S . RΔΔ】 〇〇〇…Spindle/Quil ΔΔΔ…Maximum table size

| Unit | 200QS | 110S.R16 | 130S.R22 | |

|---|---|---|---|---|

| Spindle/Quil | mm | 200 | 110 | 130 |

| Work surface | mm |

1 000×1 200 |

1 400×1 600 |

1 800×2 200 |

Spindle specification (including OP)

| Unit | 200QS | 110S.R16 | 130S.R22 | |

|---|---|---|---|---|

|

|

|

20~3 000

OP:High-speed

spindle |

5~3 000

OP:High-speed spindle |

5~2 500

OP:High-speed spindle |

| Spindle drive motor | 50%ED/continuous rating | AC30/22kW | AC15/11kW | AC22/18.5kW |

Custom spindle and work surface size (including OP)

| Support table |

Φ200 Quil |

Φ110 Spindle | Φ130 Spindle | Φ150 Spindle |

|---|---|---|---|---|

|

200QS |

Standard | ― | ― | ー |

| ***S.R16 | ※ | Standard | Option | ※ |

| ***S.R22 | ― | ― | Standard | Option |

*Technically possible, but will be discussed with you, including specifications.

Watch the BTDseries

Play on YouTube (1 minute 12 seconds)

Table-Type Horizontal Boring and Milling Machine

BTH series

Column Traverse

Large weight and tall workpieces are valid because the Z axis moves the column

Standard specifications

size:【BTH - 〇〇〇 . RΔΔ】 〇〇〇…Spindle/Quil ΔΔ…Maximum table size

| Unit | 110.R18 | 130.R24 | |

|---|---|---|---|

| Spindle dia | mm | 110 | 130 |

| Work surface | mm | 1 400×1 800 | 2 000×2 400 |

| Spindle speeds | min-¹ | 5~4 000 | 5~2 500 |

R24 is also available with a spindle diameter of 150 and a spindle speed of 4 000 min-¹.

Please feel free to contact us.

Horizontal Machining Center

BM-Q

The quill spindle provides highrigidity machining, and the wide cover with high space efficiency can handle tall workpieces.

Depending on your processing needs, you can choose from three different palettes.

Standard specifications

| Unit | BM-Q | |

|---|---|---|

| Quill | mm | 200 |

|

|

|

800×1 000 |

| 1 000×1 000 | ||

| 1 250×1 250 | ||

| Spindle speeds | min-¹ | 20~6 000 |

Horizontal Machining Center

BMC series

Stable cutting capability and high operability contribute to improved uptime.

Standard specifications

size:【BMC-〇〇〇】 〇〇〇…Pallet size

| Unit | BMC-800 | BMC-1000 | |

|---|---|---|---|

| Work surface | mm | 800×800 |

1 000×1 000 |

| Spindle speeds | min-¹ | 15~5 000 | 15~5 000 |

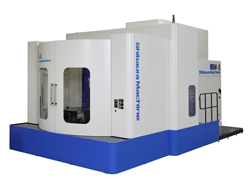

Floor-Type Horizontal Boring and Milling Machine

BF・BSF series

The size of the workpiece is less limited, and it can be used for machining large workpieces. It can also be machined with closeness by extending the quill or ram of the spindle.

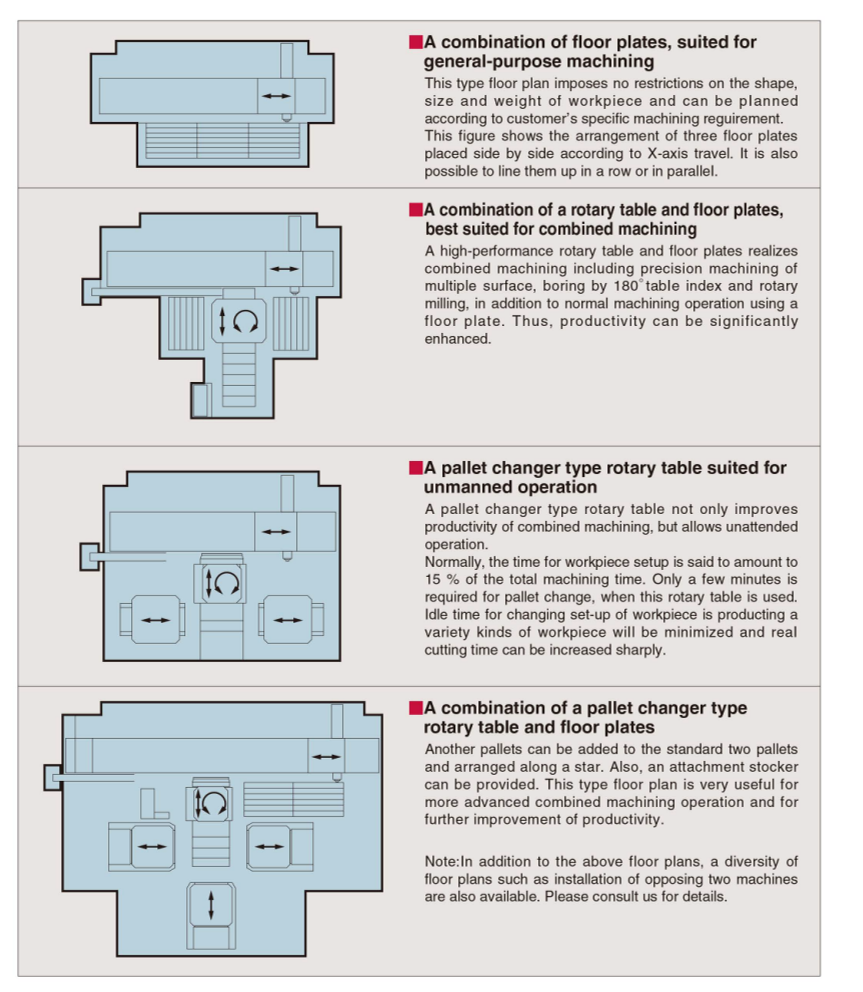

The combination of the table, attachment, and body (tandem, opposed, etc.) can be proposed according to the product and the customer's preference.

BF series

Φ360mm quill type is adopted.

Can be used with angle heads and rotating facing head for a wide range of complex machining.

CNC controller can be selected between TOSNUC and FANUC.

BSF series

380×380mm ram type is adopted.

A wide variety of attachments are available to support diversified workpiece processing.

CNC controller can be selected between TOSNUC and FANUC.

Standard specifications

| Unit | BF-130B | BSF-150C | |

|---|---|---|---|

| Hedstock or ram section | mm | Quill Φ360 |

Ram 380×380 |

| Spindle dia | mm | 130 | 150 |

| Work surface | mm | Work surface is introduced separately | |

| Spindle speeds | min-¹ | 6~1 600 | 10~3 000 |

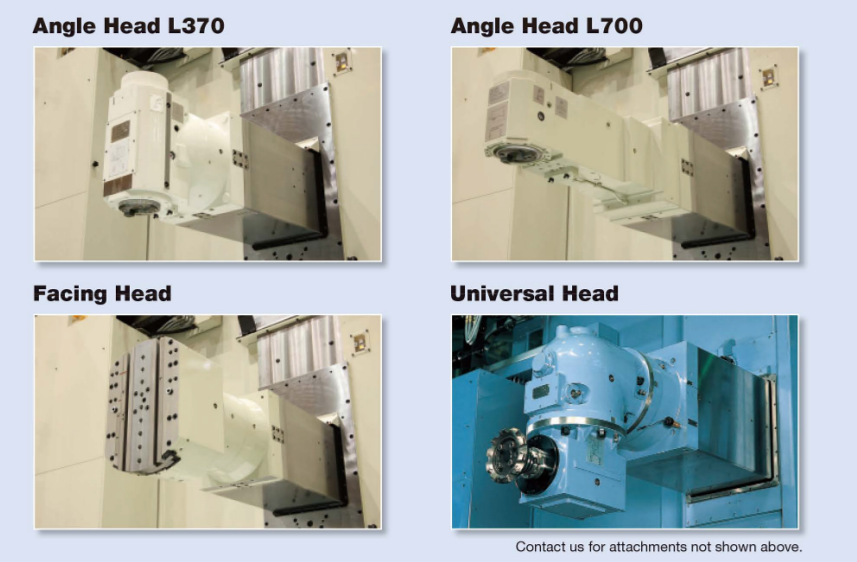

Viewing the attachments

- Angle head

- Thin angle head

- Rotating facing head

- Universal head

Machine layout