BTD-S series is a powerful horizontal boring machine with high accessibility

SHIBAURA MACHINE's Horizontal Boring Machine

Shibaura Machine's best-selling machine

has been remodeled into a high-performance, high-productivity machine.

[Features]

1. Selection of the machine according to the target workpiece of the customer

3. CNC equipment that is familiar to the user

4. Prevention of scattering of chips and cutting fluid

Features 1. Selection of machine according to the target workpiece of the customer

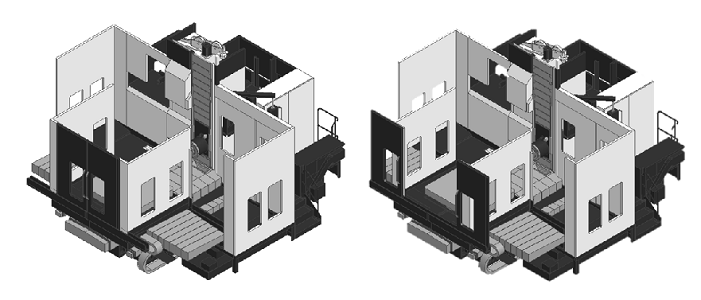

Selection of spindle head

・Quill spindle (left)/Boring spindle (right)

We have a lineup of standard "horizontal boring spindle" and "quill spindle" which is thicker around the spindle to increase rigidity.

The boring spindle and quill spindle can be fed out to any length.。

*Feeding of the spindle (structure that expands and contracts) is sometimes referred to collectively as "quill." It is distinguished as a specification of Shibaura Machine.

*Feeding machining is not possible.

| BTD-200QS | BTD-110S.R16 | BTD-130.R22 | |

|---|---|---|---|

| Φ110 Spindle (Boring Spindle) | ― | Standard |

― |

| Φ130 Spindle (Boring Spindle) | ― |

OP |

Standard |

|

Φ150 Spindle (Boring Spindle) |

― | ― | OP |

|

Φ200 spindle (quill spindle) |

Standard | ― | ― |

| High Speed Type 4 000 Rotating Spindle | ― | OP | OP |

|

High Speed Type 5 000 Rotating |

OP |

OP |

― |

|

High Speed Type 8 000 Rotating |

― |

OP |

OP |

|

long nose |

― |

OP |

OP |

OP:Special Accessories

Standard accessories

| Accessories | Unit | BTD-200QS | BTD-110S.R16 | BTD- 130S.R22 |

|---|---|---|---|---|

| Spindle diameter | mm | ― | 110 | 130 |

| Quill diameter | mm | 200 | ― | ― |

| Maximum spindle speed | min-¹ | 3 000 | 3 000 | 2 500 |

| X Axis travel | mm | 1 500 | 2 000 | 3 000 |

| Y Axis travel | mm | 1 200 | 1 500 | 2 300 |

| Z Axis travel | mm | 700 | 1 450 | 1 600 |

| W Axis travel | mm | 400 | 500 | 700 |

| Table working surface | mm | 1 000 × 1 200 | 1 400 × 1 600 | 1 800 × 2 200 |

| Table loading capacity | kg | 4 000 | 6 300 | 12 000 |

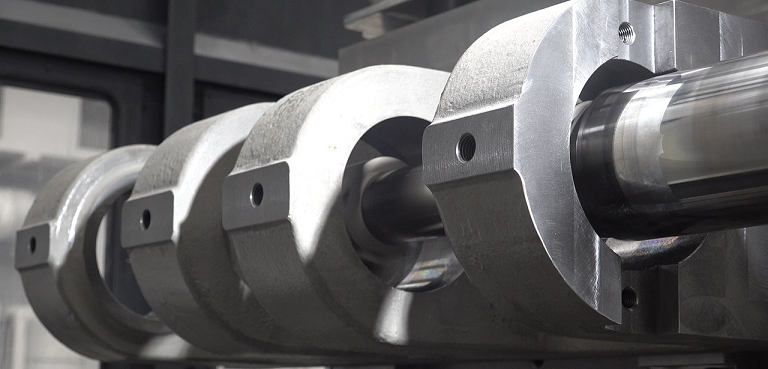

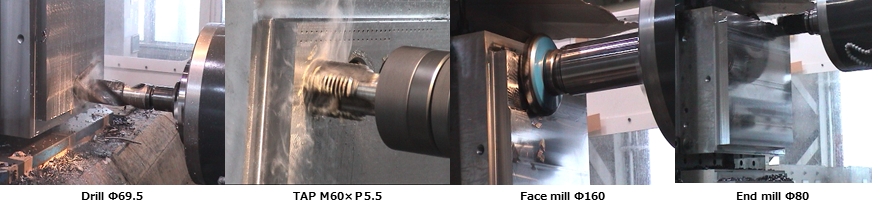

Features 2. Reduced cycle time

It contributes to shortening cutting time by improving rapid traverse and feedrate.

| Accessories | Axis | Unit | 200QS | 110S.R16 | 130S.R22 |

|---|---|---|---|---|---|

|

|

X,Y,Z |

m/min |

(12) →15 | (12) →15 | (10) →12 |

| W | (5) →6 | 6 | 6 | ||

| B | °/min | 1 080 | 720 | 720 | |

| Maximum feedrate | X,Y,Z | mm/min | (6 000) →10 000 | (6 000) →10 000 | (4 000) →5 000 |

※For comparison with the BTD-H series, (in parentheses) are the numbers for BTD-200QH, 110H.R16,130H.R22.

Features 3. Familiar CNC equipment

| CNC equipment | |||

|---|---|---|---|

| Type |

TOSNUC PX200 |

FANUC 31i-B Plus | |

|

|

|

|

|

NC operating panel: vertical +Handwheel feed unit |

NC operating panel: horizontal Pendant type machine operation box (with position indicator) +Handwheel feed unit |

NC Panel Pendant Integrated specification +Handy machine operator's panel |

|

| 200QS | Standard | OP※1 | Standard |

|

***S.R16 |

― | Standard | Standard |

| ***S.R22 | ― | Standard | Standard |

※The NC function includes special accessories.

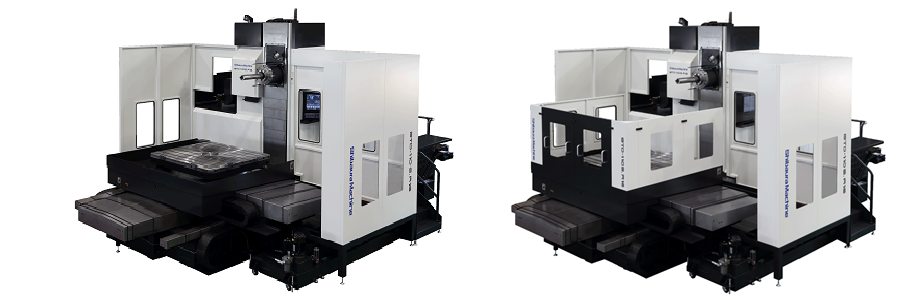

Features 4. Prevention of scattering of chips and cutting fluid

Standard accessories

-

Operator side cover

Controls scattering of chips and cutting fluid and protects workers.

Electromagnetic lock reduces human errors. -

ATC side cover

Controls scattering of chips and cutting fluid and protects workers. -

Rear cover

-

Rear fence

※BTD-200QS is not selectable.

OP:Special Accessories

-

Chip cover A

Simple and detachable

height from the table top is 1 000 mm

※BTD-200QS comes standard. -

Chip cover MS half

With manual sliding door (no ceiling)

Minimum cover height from table top: 1 870 mm -

Tool magazine guard B

Suppresses scattering of chips and cutting fluid to protect workers.

The tool passage of the ATC side screen cover is closed with an automatic shutter.

※“ATC side cover” at “Standard accessory” is not included. -

Rear step

※"Rear fence " at “Standard accessory” is not included.

※Because of the structure of BTD-200QS, you can choose chip cover A at standard accessories or the chip cover MS half at special accessories.

Reference example:BTD-110S.R16

Standard accessories OP:Chip cover A

OP:Chip cover MS half