DC-R Series(Large-sized machine)

Features of the Die Casting Machine “DC1100/1300R-E”

The world's first full-scale electrified large die casting machine We aim to realize "new 3S" based

on the abundant know-how cultivated in small to medium-sized machines.

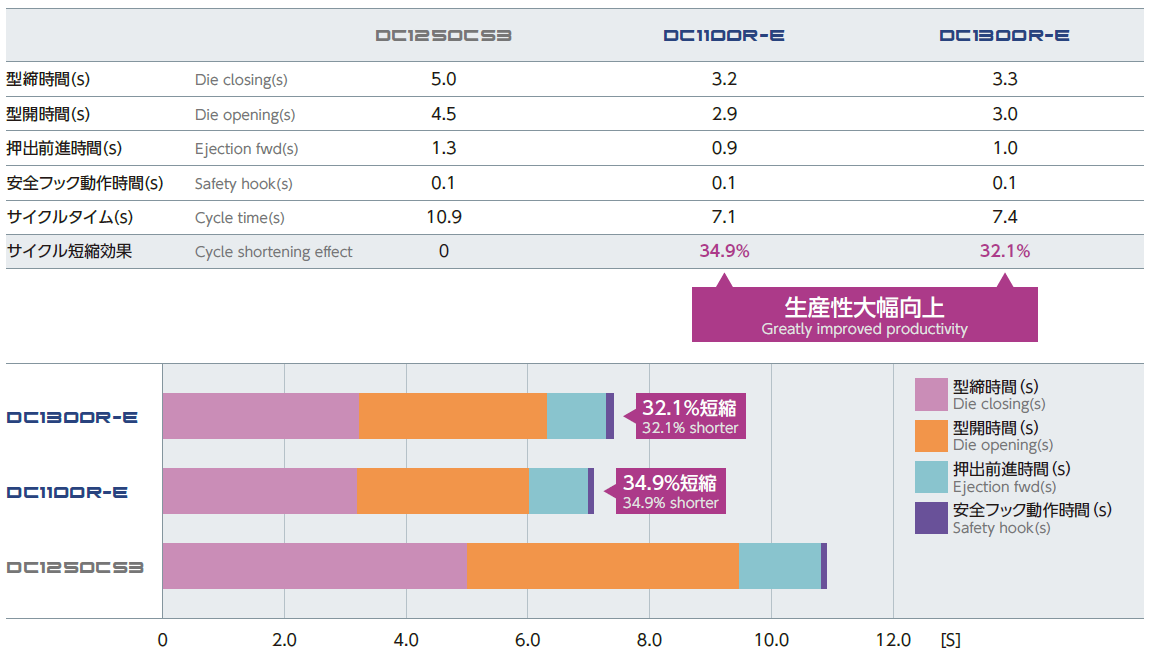

Reduced cycle times

Cycle comparison

With the use of an electric mold clamping system

■ At the same time that the mold opens, the medium action is possible.

■ Splay action and clamping action can be interlocked to shorten the spray time. (Option)

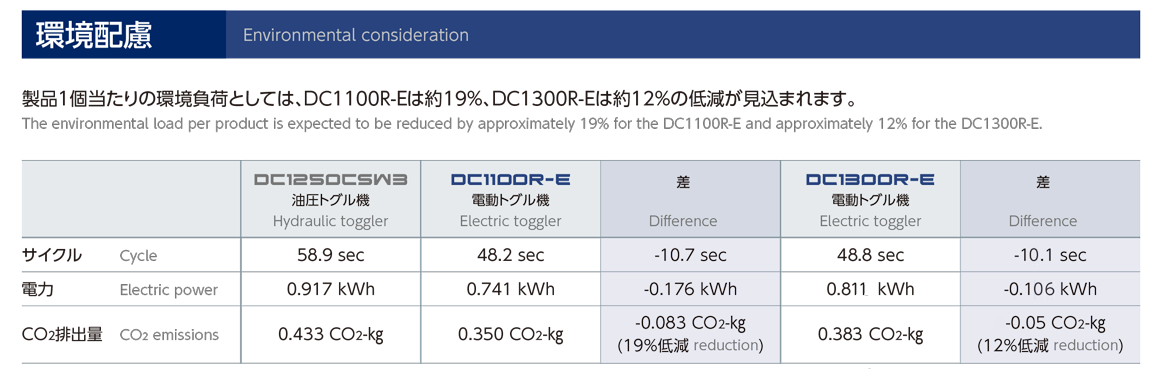

Environmental consideration

※Calculated as 0.472 kilograms of CO₂ in 1kWh(this figure is not a guaranteed value in the trial calculations)

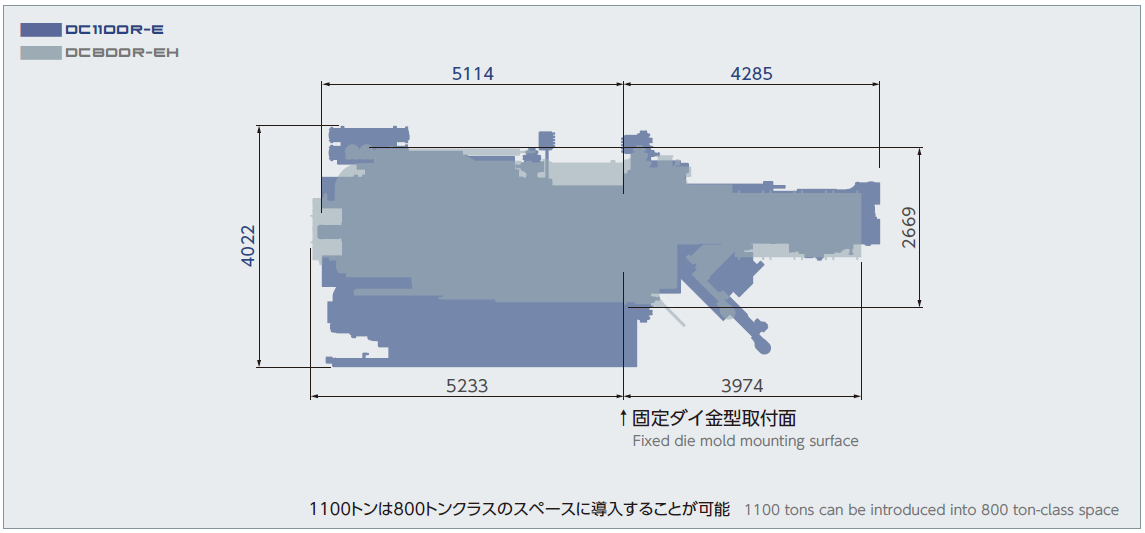

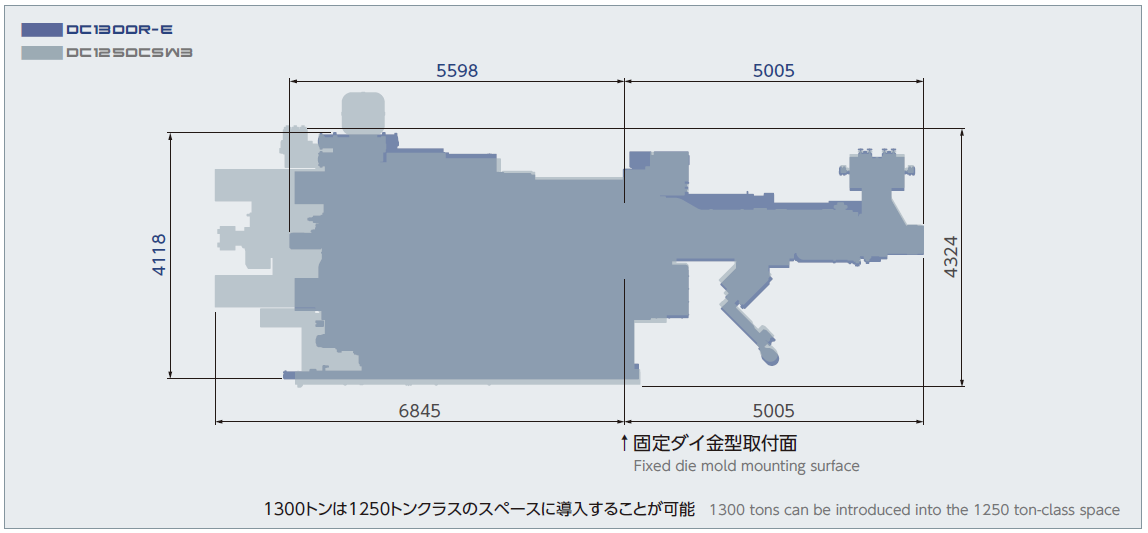

Saving space

The frame is shortened by decreasing the capacity for the frame tank.

Space saving is achieved by placing a hydraulic motor on the side of the frame.

◇DC1100R-E can be introduced into 800 ton-class space

◇DC1300R-E can be introduced into the 1250 ton-class space

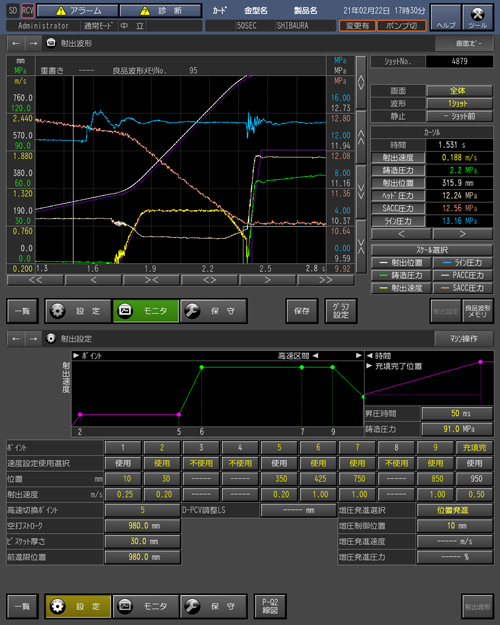

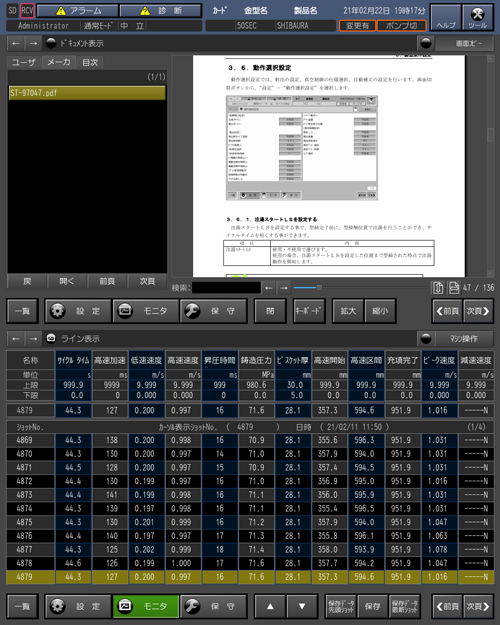

Control device TOSCAST-999

In the R series, all largest models were equipped with the control device (TOSCAST-999) as the standard. The large screen improves the operator's maintenance and management environment.

Pressure boost control can be selected from position/speed/pressure.

Compared with the conventional position-based start control, the new

control system has been developed to start the intensification always

at the same timing even with the ladling volume variation. It is effective

in case of higher fast shot speeds and/or using the slowdown control.

Multilingual support and input regulation management are possible, and global production management can be streamlined.

In addition, Shibaura Machine's original fault diagnostic function is equipped with the standard, and dPAQET (optional) will contribute to the improvement of maintenance and productivity.

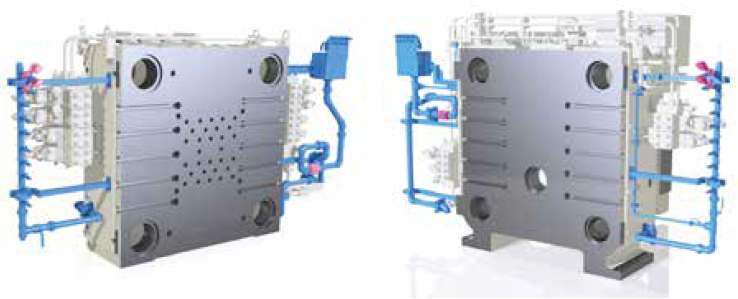

Sensing cooling specifications (Option)

Equipped with a controllable solenoid valve at

two inlets on the water supply side of the

standard cooling specification and a flow meter at

the drainage side enables temperature control of

the mold, thus stabilizing product quality.