High Precision Machining Center UVM Series

Machining Examples

Direct machining of cemented carbide: bevel gear forging die

Machine: UVM-450D(H)

Material: Cemented carbide (VM-40 90HRA)

Tooling

Rough: R1 mm diamond coated ball end mill

Finish: R1 mm PCD ball end mill

Machining accuracy

Pitch deviation (Fp, fp, fu): 1 μm or less

Pitch line run-out (Fr): 0.7 μm

Surface roughness: 17 nm Ra

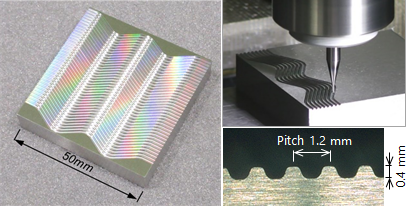

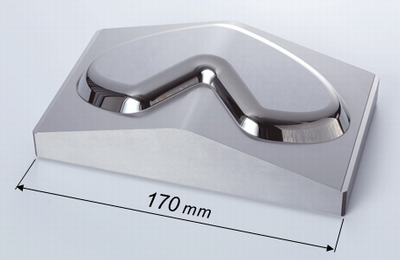

Press die for fuel cell metal separator

Machine: UVM-450C(H)

Material: Tool steel (62HRC)

Finishing tool: R0.2 mm cBN ball end mill

Dimensional accuracy: ±1 μm

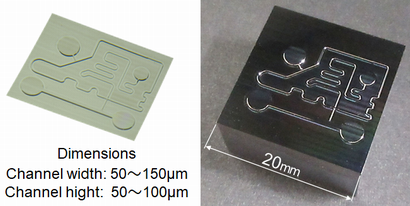

Microfluidic chip mold

Machine: UVM-450D(H)

Material: Electroless nickel phosphorus plating

Finishing tool: Φ0.2-R0.01 mm single crystal diamond corner radius end mill

Dimensional accuracy: ±1 μm

Surface roughness: 2~5 nm Ra

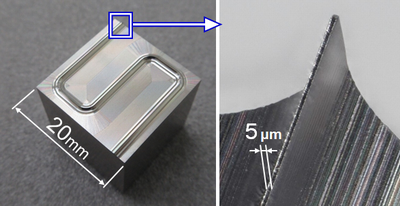

Cemented carbide engraving blade

Machine: UVM-450C(H)

Material: Cemented carbide (VF-20 92.5HRA)

Finishing tool:R0.5 mm diamond coated ball end mill

Dimensional accuracy: ±1 μm

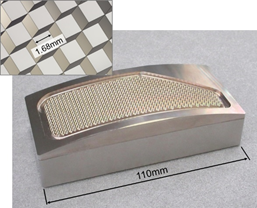

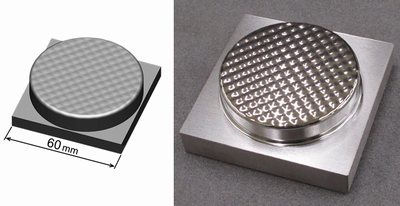

Reflex reflector mold

Machine: UVM-450D(H)

Material: Electroless nickel phosphorus plating

Finishing tool: R0.1 mm single crystal diamond ball end mill

Surface roughness: 12 nm Ra

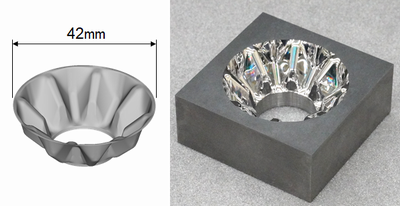

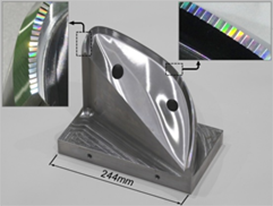

Light-guide mold for clearance lamp

Machine: UVM-700E(5AD)

Material: Pre-hardened steel (40HRC)

Finishing tool: R0.1 mm cBN ball end mill

Surface roughness: 19 nm Ra

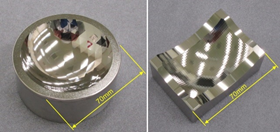

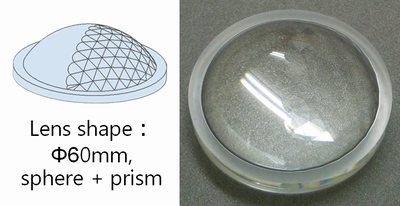

Thick solid lens mold for LED head lamp

Machine: UVM-450C(H)

Material: Electroless nickel phosphorus plating

Finishing tool: R1 mm single crystal diamond ball end mill

Surface roughness: 10 nm Ra

Thick solid lens mold for LED head lamp

Machine: UVM-450C(H)

Material: Stainless steel (52HRC)

Finishing tool: R1 mm cBN ball end mill

(Man-hours for polishing 90% decreased)

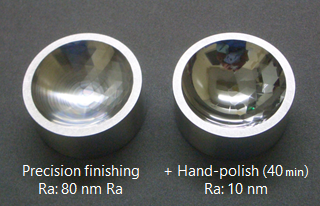

Mirror surface machining of thick solid lens

Machine: UVM-450C(H)

Material: Acrylic resin

Finishing tool: R1 mm single crystal diamond ball end mill

Surface roughness: 15 nm Ra

Mirror finish of optical parts mold: VR goggle

Machine: UVM-700E(5AD)

Material: Stainless steel (52HRC)

Top surface: Elliptical vibration cutting

Finishing tool: R2 mm single crystal diamond bite

Curved slope: PCD milling

Finishing tool: R2 mm PCD ball end mill

Form accuracy: 5 μm P-V

Surface roughness: 10 nm Ra

Mirror finish of cosmetic case design model

Machine: UVM-700E(5AD)

Material: Stainless steel (52HRC)

Finishing tool: R1 mm PCD ball end mill

Surface roughness: 4~5 nm Ra

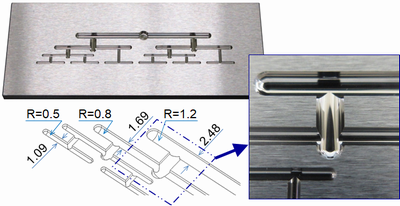

Runner part of connector mold

Machine: UVM-450D(H)

Material: Stainless steel (52HRC)

Finishing tool: R0.3, R0.5 mm cBN ball end mill

Dimensional accuracy: ±1 μm

Surface roughness: 15 nm Ra

*The above figures are measured values, not the values for guaranteeing.