High Precision Micro-grooving Machine UMP-D Series

Applications

In addition to straight-line / curved-line grooving, this series has a capability of various machining with high efficiency and high precision. It applies with up sizing of LCD and enables high precision machining of light guiding plate molds up to a maximum of 70 inches. The machine size can be selected based on the LCD size.

Features

High precision machining of fine grooves

High Precision V-V Roller Guide Way with non-circular system and linear motor drive system are equipped for the X and Y axis, realizing high rigidity and high responsiveness

Special accessory combination allows even more variable machining

- The installation of Indexing Head (C1 axis) supported by High Precision Table Type Aerostatic Bearing Spindle enables highly precise turning.

- The installation of Tool Swivel Slide (C2 axis) enables highly precise curved-line grooving.

- The installation of Tool Indexing Head (A axis) enables highly precise tool edge aligning adjustment.

- The installation of a spindle (rotation speed 10000min-1) enables fly-cutting.

The Cross Rail and Column are monoblock cast, and a strong and stable machine structure is provided.

Active Type Isolator is equipped. In addition to vibration feedback, feed forward control of machine position enables machining precision is increased to the limit.

Main Specifications

|

Main Specifications |

UMP- |

UMP- 6585D |

UMP- 65105D |

||

|---|---|---|---|---|---|

| Applied LCD size (16:9) |

Inch |

22 (487×274) |

33 (735 x 415) |

42 (930 x 525) |

|

| Table (Vacuum Chuck Table is optional) |

Working surface | mm | 500 x 400 | 750 x 600 | 950 x 600 |

| C1 axis equipped | mm | φ400 | φ700 | ||

| Table allowance load | C1 axis, including Sub-table | kg | 100 (*) | 500 (*) | 600 (*) |

| C1 axis equipped | kg | 30 | 100 | ||

| Travel | X (Cross movement of Table) | mm | 600 | 850 | 1050 |

| Y (Longitudinal movement of Saddle) | mm | 450 | 650 | ||

| Z (Vertical movement of Tool) | mm | 100 | 150 | ||

| Maximum feedrata | X: 15000 mm/min Y: 9000 mm/min Z: 3000 mm/min C1: 300 min-1 |

||||

| Programming resolution | X, Y, Z: 0.001µm A, C: 0.00001deg |

X: 0.01µm Y, Z: 0.001µm A, C: 0.00001deg |

|||

| Machine mass | kg | Approx. 5800 | Approx. 10000 | Approx. 12000 | |

| Main Specifications | UMP-65120D | UMP-160160D | ||

|---|---|---|---|---|

| Applied LCD size (16:9) | Inch (mm) | 48 (1065 × 600) | 70 (1550 × 860) | |

| Table (Vacuum Chuck Table is optional) | Working surface | mm | 1100 × 600 | 1400 × 1550 |

| C1 axis equipped | mm | φ700 | φ800 | |

| Table allowance load | C1 axis, including Sub-table | kg | 650 (*) | 400 (*) |

| C1 axis equipped | kg | 100 | 100 | |

| Travel | X (Cross movement of Table) | mm | 1200 | 1600 |

| Y (Longitudinal movement of Saddle) | mm | 650 | 1600 | |

| Z (Vertical movement of Tool) | mm | 150 | 150 | |

| Maximum feedrata | X: 15000 mm/min, Y: 9000 mm/min, Z: 3000 mm/min | |||

| Programming resolution | X: 0.01μm; Y, Z: 0.001μm; A, C: 0.00001 deg | X, Y, Z: 0.001 μm; A, C: 0.00001 deg | ||

| Machine mass | kg | Approx. 13500 | Approx. 25000 | |

(*) Contact Sales Department as an allowance load is depending on the Table specifications.

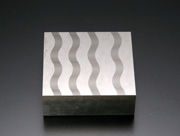

Machining Examples