High Precision Slicing Machine USM Series

Machining Examples

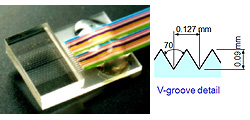

V-grooving for an optical communication connector

Workpiece material: Quartz, Pyrex

V-groove: 70 degrees, 48 grooves per connector

Number of connectors per substrate: 10 connectors x 4 rows = 40 connectors

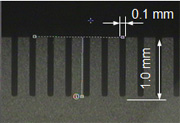

Grooving on ceramics

Workpiece material: Alumina ceramics

Groove: width 0.1 mm, depth 1 mm, pitch 0.3mm

Number of machining paths: 1 path

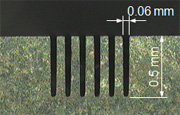

Grooving on tungsten carbide

Workpiece material: Tungsten carbide (90HRA)

Groove: width 0.06 mm, depth 0.5 mm, pitch 0.12 mm

Number of machining paths: 1 path

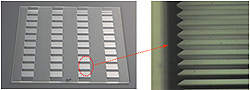

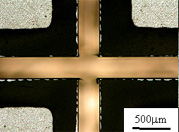

Dicing of LED heat sink

Workpiece material: Aluminum-alumite

(width 7.5, length 79, thickness 1.025 mm)

Dicing pitch: 3.205 x 5.825 mm

Blade: φ2 inch x t0.3 mm

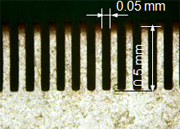

Grooving on resin material

Workpiece material: VESPEL ® (wholly aromatic polyimide resin)

Groove: width 0.05 mm, depth 0.5 mm, pitch 0.1 mm

Number of machining paths: 1 path

(VESPEL ® is a registered trademark of DuPont.

Cutting of copper foil

Picture of cross section

Workpiece material: Copper foil (0.1 mm thick)

Diamond turning tool: Nose angle 44 deg./dry cutting