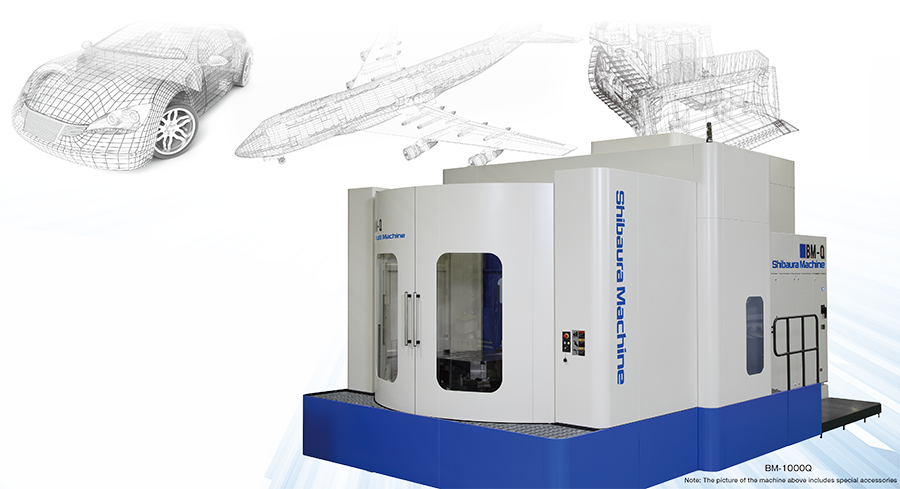

BM Series

Horizontal Machining Center BM series

Horizontal machining centers with the highest level of precision in a class created by bringing together the technical capabilities of Shibaura Machine, and achieving a further evolution of machining technology

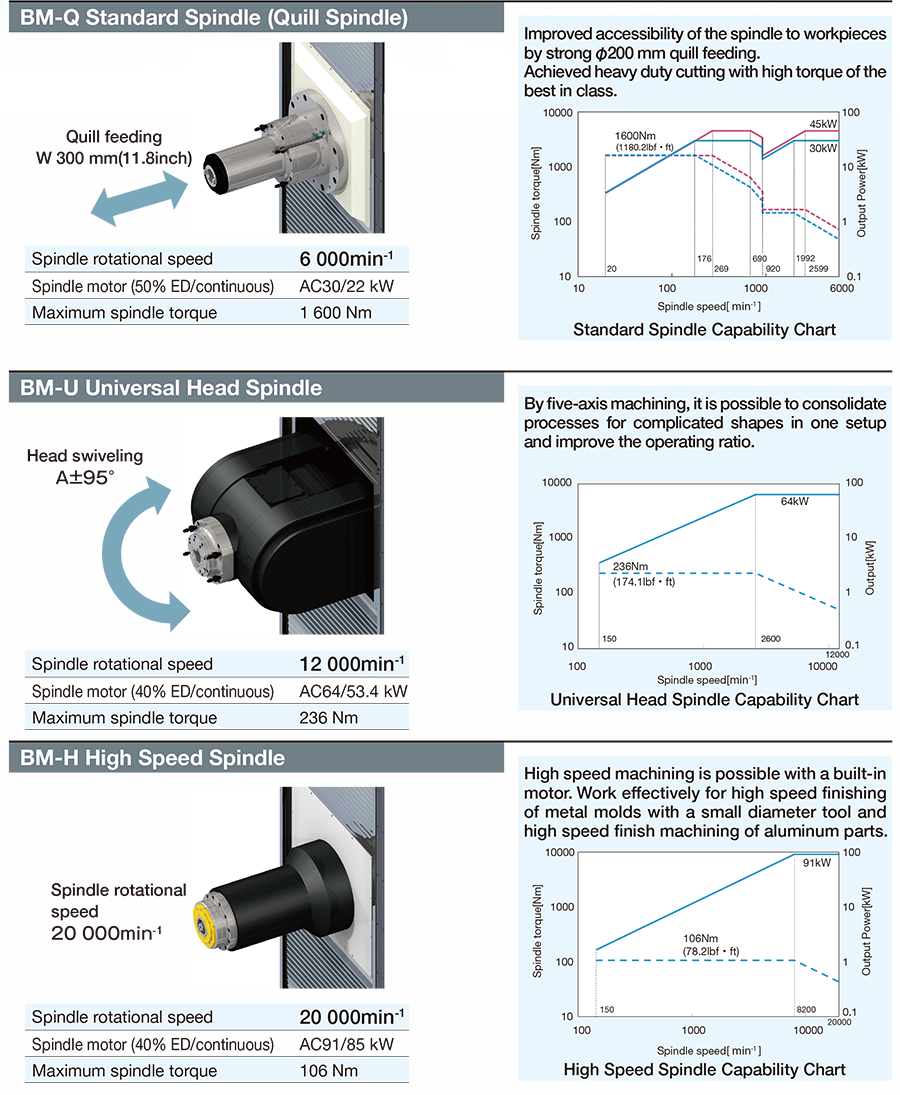

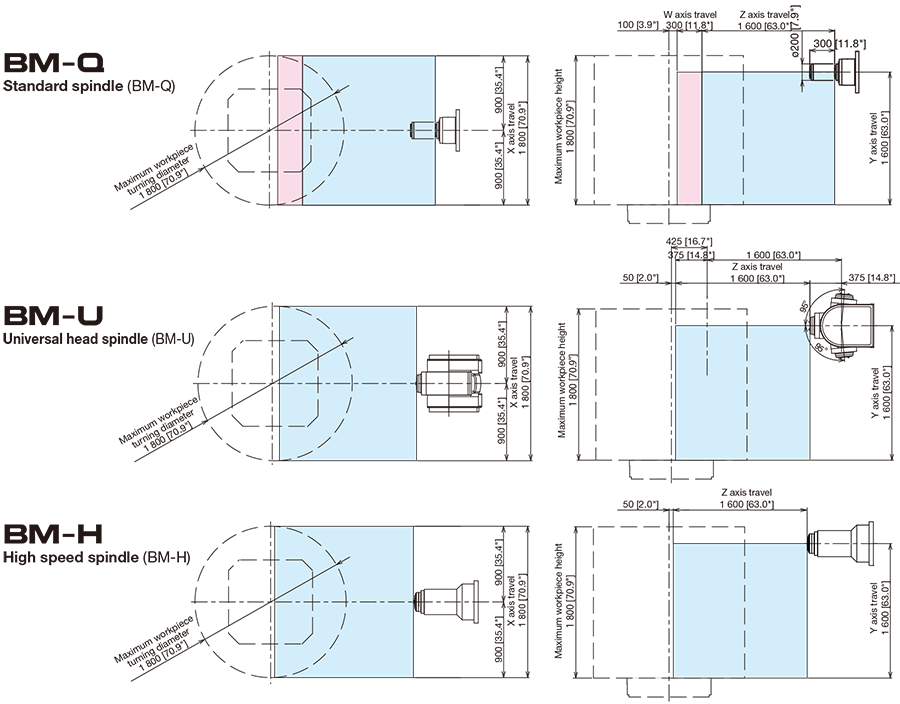

Spindle Lineup

A wide variety of spindles support diversified workpieces

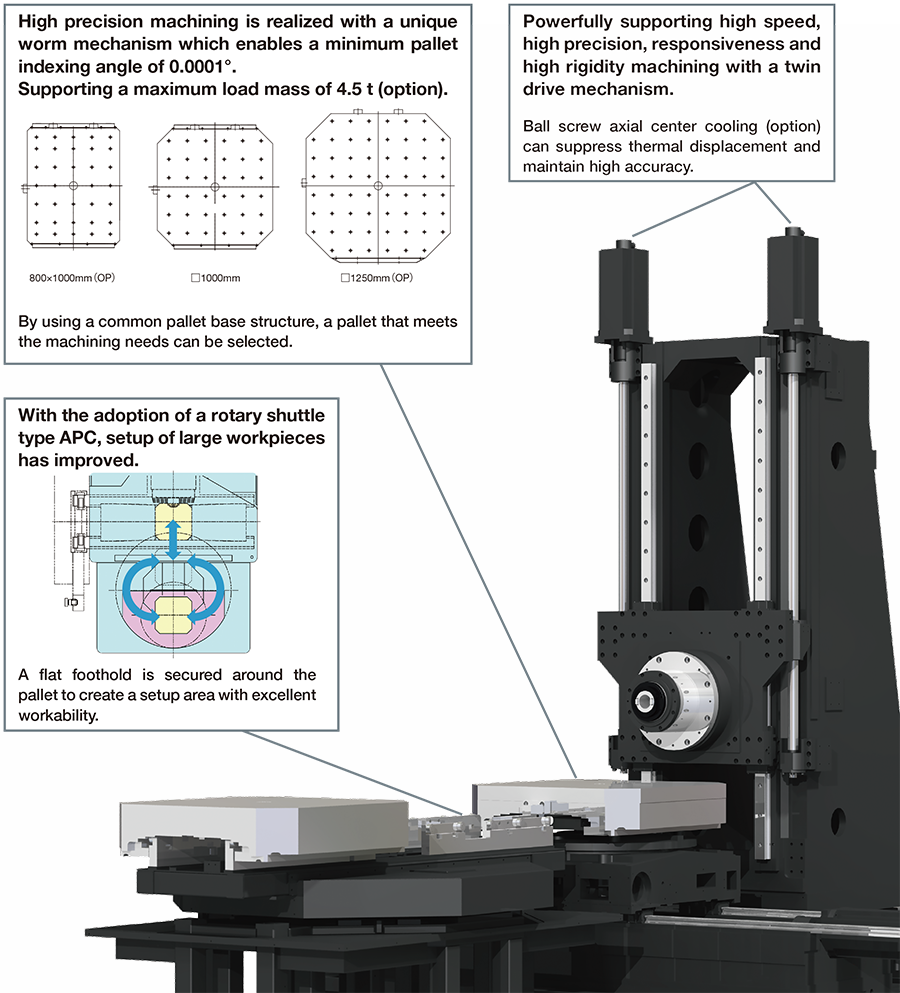

Mechanical Structure

Further optimization with inherited high rigidity and by FEM analysis.Speed increased to fast forward speed of 40 m/min and cutting feed speed of 25 m/min.

High efficiency machining of large workpieces is realized,promising productivity improvement.

New Design Pursuing Workability

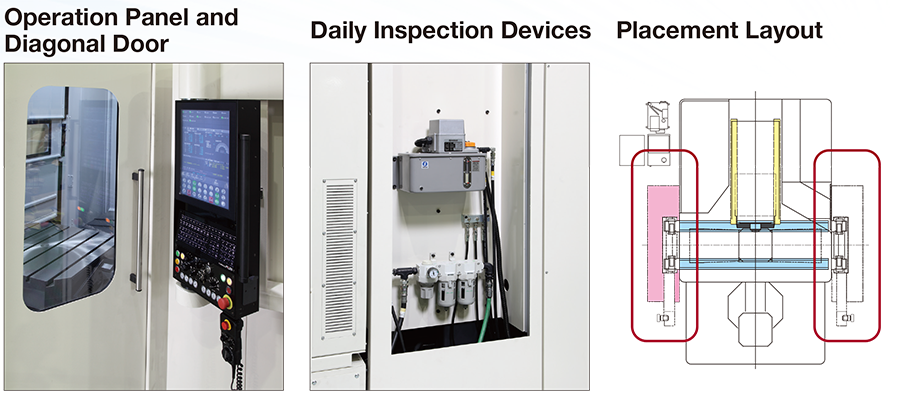

- Operation Panel and Diagonal Door

- Improved operability and visibility achieved with the operation panel that can rotate from 0 to 90 degrees and the diagonal door.

- Daily Inspection Devices

- Easy maintenance achieved by placing the devices that require daily inspection together on the back panel of the machine.

- Placement Layout

- The chip conveyor and the coolant unit can be installed on either the left or the right depending on the layout. (Supported as an option)

Axis travel

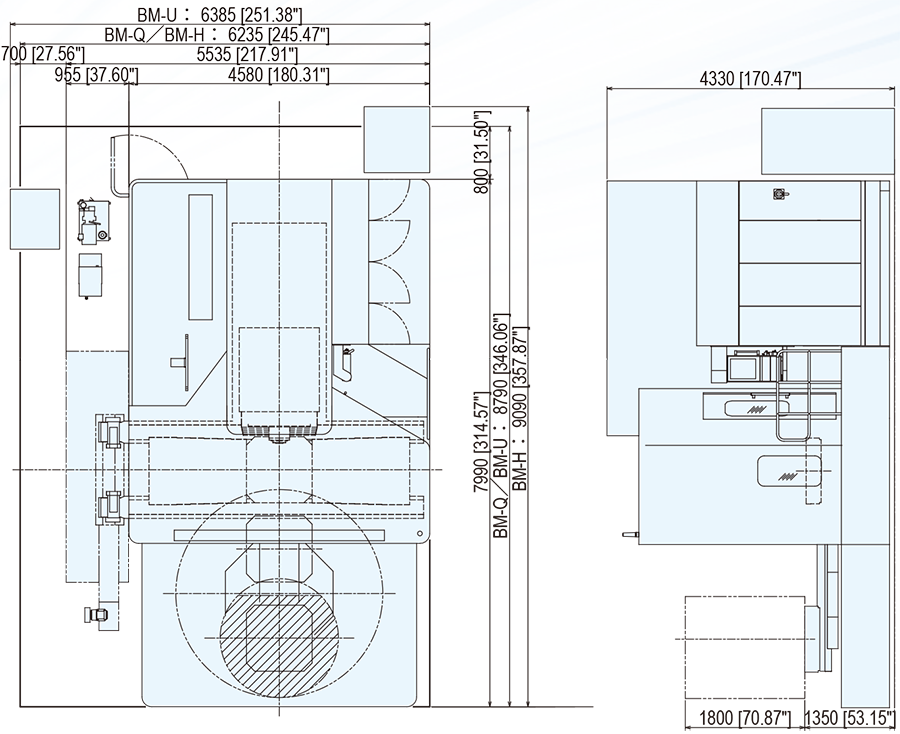

Machine general view

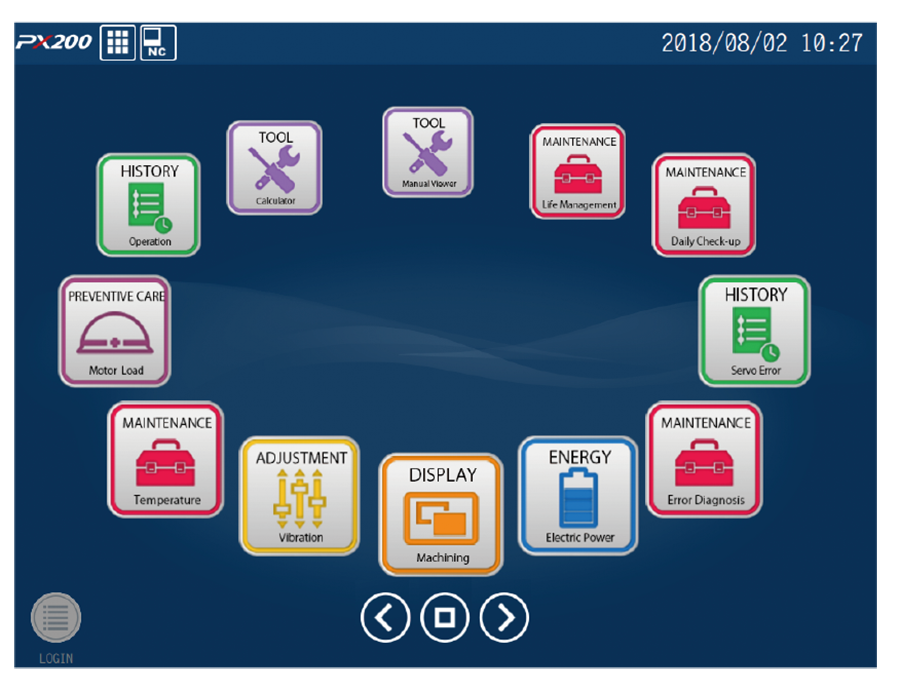

TOSNUC PX200

- Electro-mechanical integrated CNC for professional use (field) made by a machinery manufacturer.

- CNC that supports operation with a simple & smart operation.

- CNC that responds to a wide range of applications from manual machining to automatic machining in a production control system.

- CNC to quickly detect abnormalities in the machine with an enhanced diagnostic function to improve the operating ratio.

New Machining Assist Functions

Operator Support

- Machining Screen

- Information necessary for machining is consolidated on one screen.Expanded coordinates and detailed factors at the time of alarm occurrence are displayed with one touch.

- Manual Viewer

- Browsing of manuals for machines and NCs.Keyword search is possible for all manuals.

Machining Support

- Sensorless Cutting Force Detection

- Real time monitoring of cutting forces during machining.Detection of machining abnormalities and protection of workpieces and tools.

- Work Weight Setting

- Simply follow the instructions on the screen and set the weight of the workpiece.Machining suitable for workpiece weight is realized.

Preventive Maintenance and Monitoring

- Operation Status List

- The machine operation status and the operating ratio are displayed in graphs and with numerical values.The list can be displayed on a weekly or monthly basis.

- Daily Inspection

- Daily inspection can be performed on the screen.Results can be saved in pdf format by easy operation.

- Maintenance

- Detailed data when some malfunction occurs in the mechanical system is saved.Factor analysis is possible with graphs and other data at a later time.

Features of the Operation Panel

- Flush Surface

- Simple and timeless design

- HMI(Human-Machine Interface)

- Adopted 19-inch vertical touch panel type

- Smartphone-like intuitive operation

- Enabling input while wearing gloves

- Keyboard

- Adopted mechanical keys with a sense of luxury

- Adopted QWERTY keyboard layout to improve operability

- Operation Switches

- Easy-to-see operation is realized with HMI and mechanical switches

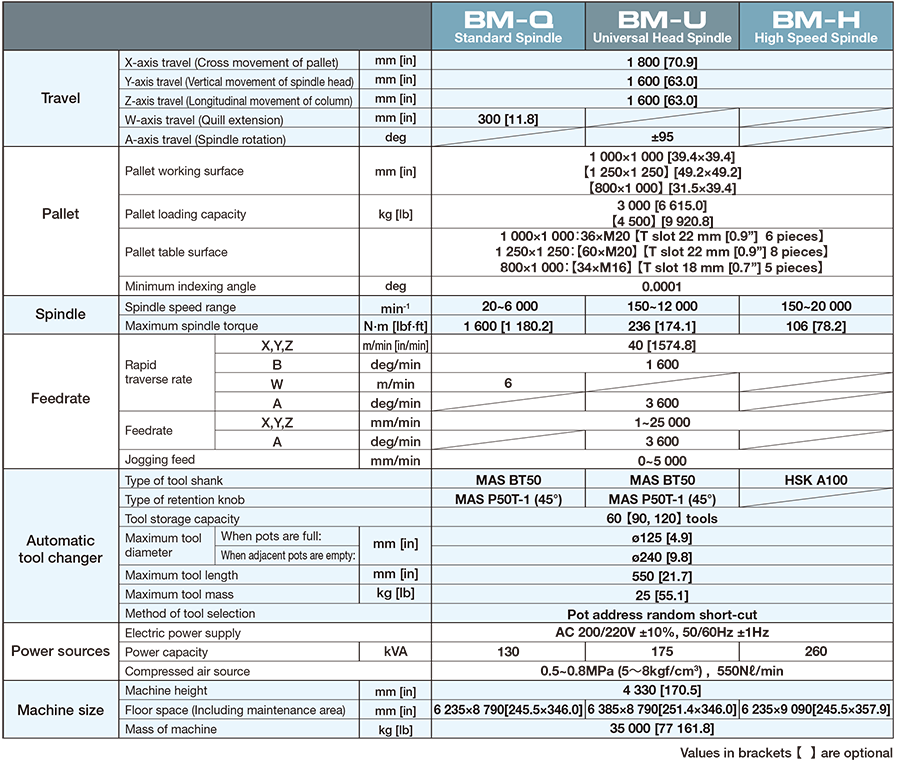

Machine specifications