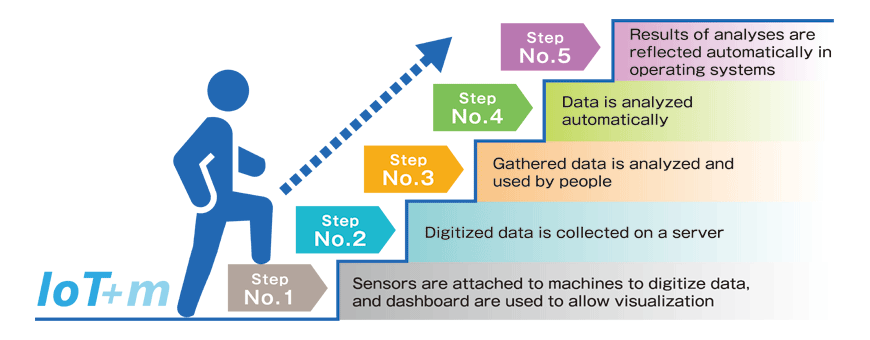

IoT+m Implementation Step

Shibaura Machine's IoT starts from the visualization and digitalization of machines and proceeds towards conversion of the customer's factory into a smart factory in a step-by-step process in tandem with the customer.

The first step in IoT is to digitize and store useful data. Next, this is analyzed by humans for assisting in resolving issues and building a knowledge base. Once enough data has been collected, AI or another method is used to automatically conduct analysis. The ultimate goal is to automatically apply the analysis results.

IoT+m System Example

Common Features

- Machine Status Visualization

- Predictive Maintenance by using TM Smart Sensors

| Machine Type | System Example |

|---|---|

| Machine Tools | mPAQETTM / Actual Running Data Collection |

| Injection Molding Machines | iPAQET®/ Production Monitoring by Actual Collecting Data |

| Die Casting Machines | dPAQET® / Prodiction Monitoring by Actual Collecting Data |

| Extrusion Machines | ePAQET® / Production Monitoring Based on Actual Collected Data |

| Robot | rPAQETTM / Operation Monitoring |

Machines from Shibaura Machine are provided with application software for data collection and monitoring that is specific to that machine type.

This software includes mPAQET for machine tools, iPAQET for injection molding machines, dPAQET for die casting machines, ePAQET for extrusion machines, and more, and this lineup is collectively called xPAQET. Normally, one type of software application from xPAQET is provided and installed on the edge computer upon request by the customer.