High Precision Optical Glass Molding Press Machine GMP Series

Main Specifications

Optical Glass Molding Press Machine (Die-Molding Fix System)

- Line up provided to match your needs from small diameter to large diameter (Maximum diameter 150mm)

- High temperature molding machine for fused silica molding is provided.

- Automatic operation is available with Auto Loader (optional) for glass materials and molded parts.

| Main Specifications | GMP-311V | GMP-315VW | GMP-0204V |

|---|---|---|---|

| Maximum mold diameter (mm) |

φ 65 - φ 110 (Diameter 150mm/option) |

φ65 - φ110 | φ40 |

| Molding process measure | Die-molding fix system | ||

| Chamber number (press axis number) | 1 (2 maximum / option) | 1 (each 1 axis for upper and lower) | 1 |

| Heating measure | Infrared | ||

| Maximum heating temperature (℃) | 800 | 800 | 800 |

| Maximum pressing force (kN) | 30 (40 / option) | 30 (40 / option) | 2(0.5/00504V) |

| Pressing power source | AC servomotor | ||

| Pressing force detector | Load cell | ||

| Mold positioning measure | Encoder | ||

| Gradual cooling, Steep cooling measure | Nitrogen gas controlled cooling | ||

| Ultimate vacuum (Pa) / vacuum molding | 0.6 or less | - | 0.6 or less |

| Auto loader for automatic operation (glass materials, molded parts) |

Option | - | - |

| Notes | Large diameter lens and multi-layout molding | Large diameter lens and multi-layout molding | Characterization of glass, simple molding, etc. |

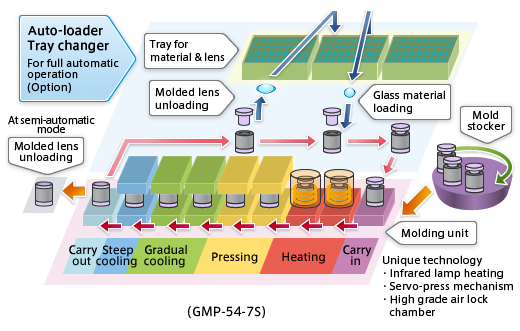

Optical Glass Molding Press Machine (Die-Molding Transfer System)

- High speed heating with infrared lamps

- Easy control and maintenance of molds and molded lenses

- Automatic operation is available

| Main Specifications | GMP-32-7S | GMP-54-7S | GMP-310V-3R |

|---|---|---|---|

| Mold diameter (mm) |

φ10 - φ 20 | φ15 - φ 40 | φ 100 |

| Molding process measure | Mold Transfer System (transferring among the individual stations of heating, pressing, gradual cooling and steep cooling) | Mold Transfer System (transferring among the individual stations of heating, pressing, cooling) | |

| Total station number | 7 stations | 3 stations | |

| Heating station number / Heating measure | 2 stations / Infrared | 1 stations / Infrared | |

| Maximum heating temperature (°C) |

Heating 1 : 600 Heating 2 : 750 |

800 | 800 |

| Press station number / Heating measure | 1 station / Heating via temperature preservative plate | 2 stations / Heating via temperature preservative plate | 1 station |

| Maximum pressing force (kN) |

3 | 5 | 30 |

| Pressing power source | AC servo motor | ||

| Pressing force detector | Load cell | ||

| Mold positioning measure | Encoder or mold contact | ||

| Gradual cooling station number / Cooling measure | 3 stations / Cooling via temperature preservative plate | 2 stations / Cooling via temperature preservative plate | - |

| Steep cooling station number / Cooling measure | 1 station / Indirect water cooling | 1 station / Indirect water cooling or Nitrogen gas controlled cooling | |

| Vacuum molding | Not available | Available | |

| Auto loader for automatic operation | Option | - | |

| Notes | Mass production for small / medium diameter lens molding | Mass production for medium / large diameter lens molding | |