Balance Chain

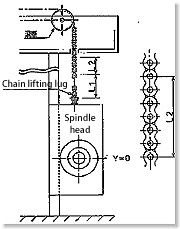

How to inspect lifting lugs for the spindle head balance chain

- Perform an inspection once a year.Timely inspections are recommended when close to wear limit.

- Move the spindle head (Y-axis) to the measurement position (lower limit).

- Identify the part of the chain that runs on the pulley most. (the most used part within the processing range)

- If the L2 length (6 pitch length) matches one in the table below, replacement is necessary.

| Machine type |

Normal pitch |

No. of pitches measured |

Normal length |

Value compared |

| BTD-200Q, 200QE |

25.4 |

6 |

152.4 |

154.7 |

| BTD-200QF |

31.75 |

6 |

190.5 |

196.2 |

| BTD-11.R16, R16 |

25.4 |

6 |

152.4 |

154.7 |

| BTD-11E.R16, R16 |

25.4 |

6 |

152.4 |

154.7 |

| BTD-13.R22, 13F.R22 |

31.75 |

6 |

190.5 |

196.2 |

| BTD-110.R13 |

31.75 |

6 |

190.5 |

196.2 |

| BTD-110.R16 |

31.75 |

6 |

190.5 |

196.2 |

| BP-110.R16 |

31.75 |

6 |

190.5 |

194.3 |

| BP-110.P20 |

31.75 |

6 |

190.5 |

194.3 |

| BP-110.P25 |

31.75 |

6 |

190.5 |

194.3 |

| BP-130.P40 |

31.75 |

6 |

190.5 |

194.3 |

| BSF |

63.5 |

6 |

381 |

392.4 |

| 50.8 |

6 |

304.8 |

313.9 |

| BF |

38.1 |

6 |

228.6 |

235.5 |

| BFT |

25.4 |

6 |

152.4 |

157 |

| BT |

25.4 |

6 |

152.4 |

157 |

| BMC |

31.75 |

6 |

190.5 |

196.2 |

| BTN |

31.75 |

6 |

190.5 |

196.2 |

PAGE TOP