Introduction of Special Machines

Customised specifications and special machines are also available, so please contact us to discuss your requirements.

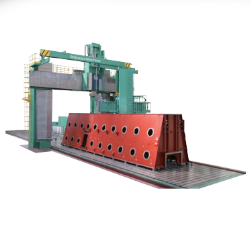

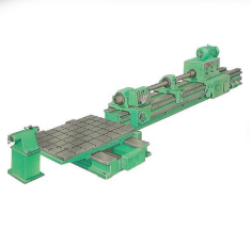

Large-Size Special Machines

Large-Size Special Machines

This product line is designed for products that are becoming larger and larger.

The rigidity of the machine is increased for faster and more accurate finishing of products.

Various attachments provide optimal machining.

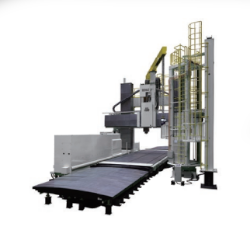

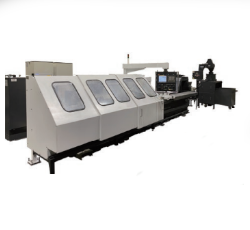

Custom Machine

Custom Machine

This model is optimized for specialized workpieces.

By optimizing the machine configuration, it contributes to improved machining accuracy and shorter machining time.

Double Column Type Machining Center

Double Column Type Machining Center

Planomiller Type

- The largest size range of Shibaura Machine's double column type machining center.

- A wide range of attachments enables machining of large workpieces without setup changes.

- Automated tool change, attachment change and indexing.

MPA series

| Track record | Unit | MPA |

|---|---|---|

| Distance between columns | mm | 4 500,5 000,5 500,6 000,7 000 |

| Axis travel | mm | 22 200×6 250 ×2 300 ~ 28 500×8 000×3 000 |

| Table size | mm |

4 500 × 23 000 ~ 6 000 × 26 500 |

| Spindle speeds | min-¹ | 5 ~ 1 200 |

| Spindle drive motor | kW | 100(cont.) |

MPB series

| Track record | Unit | MPB |

|---|---|---|

| Distance between columns | mm | 4 500 |

| Axis travel | mm | 11 800 × 5 250 × 1 350 |

| Table size | mm |

11 800 × 11 500 |

| Spindle speeds | min-¹ | 10 ~ 2 000 |

| Spindle drive motor |

kW |

55(cont.) |

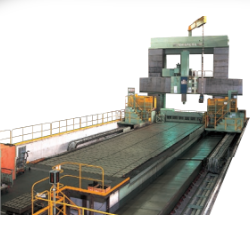

Double Column Type Machining Center

Double Column Type Machining Center

Gantry Miller

- The table is fixed and the column moves, enabling the machining of heavy parts (e.g. very large parts).

- Compared with table-moving models, the absence of a bed saves space.

MG series

| Track record | Unit | MG |

|---|---|---|

| Distance between columns | mm | 6 500 ~ 8 500 |

| Axis travel | mm | 22 500 × 6 350 × 2 300 ~16 000 × 8 500 × 2 300 |

| Table size | mm |

4 900 × 20 000 ~ 7 400 × 14 400 |

| Spindle speeds | min-¹ | 5 ~ 1 200 |

| Spindle drive motor | kW | 50 ~ 100(cont.) |

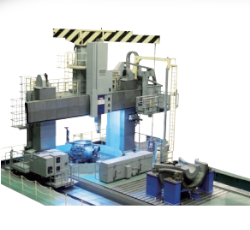

Double Column Type Machining Center

Double Column Type Machining Center

Turn Miller

- Excellent customisability, e.g. by combining rotary and plain tables.

- Combination with a turning table enables efficient machining of turning, boring and milling operations without any set-up changes.

- The machine is a travelling column type with 6-axis control (X,Y,Z,W,B,C).

TMG series

| Track record | Unit | TMG-70130 | TMG-85150 |

|---|---|---|---|

| Axis travel | mm | 13 600 × 6 500 × 2 000 | 15 000 × 8 500 × 2 300 |

| Table size | mm | 6 000 × 5 500 | 7 000 × 6 090 |

| Table dia. | mm | 5 500 | 5 000 (rotary) |

| Spindle speeds | min-¹ | 20 ~ 2 000 | 5 × 1 200 |

| Spindle drive motor | kW | AC 50 ~ 100(cont.) | DC 90 |

| Table speeds | min-¹ | 0.5 ~ 50 | 0.3 ~ 31.5 |

| Table drive motor | kW | DC 75 | DC 90 |

Floor-Type Horizontal Boring and Milling Machine

Floor-Type Horizontal Boring and Milling Machine

Ram Type

- Compensation mechanism to minimise various deformations and displacements with square ram structure spindle head.

- A wide range of attachments for improved machining efficiency.

- Selectable tables, such as surface plate type and rotary table.

BSF series

| Track record | Unit | BSF-150C | BSF-160 | BSF-180B |

|---|---|---|---|---|

| Spindle dia. | mm | 150 | 160 | 180 |

| Ram size | mm |

380 × 380 |

420 × 420 |

500 × 500 |

| Spindle travel | mm |

750 ~ 1 200 |

||

| Ram travel | mm |

750 ~ 1 400 |

||

| Spindle speeds | min-1 | 10 ~3 000 | 10 ~ 2 000 | 5 ~ 1 800 |

| Spindle drive motor | kW | 30(cont.) | 45(cont.) | 60(cont.) |

Vertical Boring and Turning Mill

Vertical Boring and Turning Mill

Turn Miller

- Square ram structure turret with compensation mechanism to minimise various deformations and displacements.

- Wide range of attachments for improved machining efficiency.

TD series

| Track record | Unit | TD |

|---|---|---|

| Table dia. | mm | 4 000 ~ 8 000 |

| Max. swing | mm |

6 000 ~ 12 500 |

| Max. cutting height | mm |

3 400 ~ 5 500 |

| Table speeds | min-1 | 25 ~ 80 |

| Table drive motor | kW | 22 ~ 100(cont.) |

Vertical Boring and Turning Mill

Vertical Boring and Turning Mill

Turning Center

- Combined machine for turning and milling with Y-axis drive.

- Attachments can be selected according to the customer's wishes.

TMT series

| Track record | Unit | TMT-40/50 |

|---|---|---|

| Table dia. | mm | 4 000 |

| Max. swing | mm |

5 000 |

| Max. cutting height | mm |

1 500 ~ 2 500 |

| Table speeds | min-1 | 80 |

| Table drive motor | kW | 100(cont.) |

Generator Roter Milling Machine

Generator Roter Milling Machine

MGR series

| Track record | Unit | MGR |

|---|---|---|

| Maximum cutting diameter | m | 2 |

| Maximum roter length | m | 20 |

| Maximum roter weight | ton | 270 |

Propeller Wing Surface Processing Machine

Propeller Wing Surface Processing Machine

MBP series

| Track record | Unit | MBP-81 | MBP-110G |

|---|---|---|---|

|

Maximum propeller cutting diameter |

m | 8.1 | 11 |

| Gantry(X) | m | - | ±1 |

| Head cross(Y) | m | Right 5.42 | Right 7.5 |

| Ram vertical(Z) | m | 2.1 | 2.5 |

| Head rotation(A) | deg | 1 135 ~ +180 | |

| Attachment rotation(B) | deg | 360(cont.) | |

| Table rotation(C) | deg | 360(cont.) | |

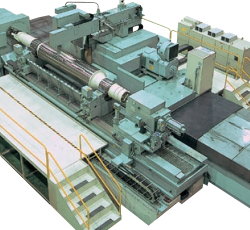

Horizontal Confront Type Machining Center

Horizontal Confront Type Machining Center

FMC series

| Track record | Unit | FMC |

|---|---|---|

| Axis travel | mm | 5 100 ~ 13 300 × 1 000 ~ 2 000 × 750 ~ 1 100 |

| Table size | mm | 4 500 ~ 11 000 × 800 ~ 1 750 |

| Spindle speeds | min-1 | 20 ~ 3 000 |

| Spindle drive motor | kW | 26(cont.) |

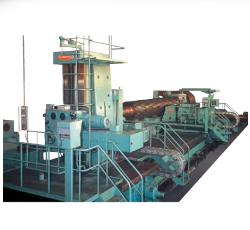

Roll Grinding Machine

Roll Grinding Machine

Table Travers

KT series

| Track record | Unit | KT |

|---|---|---|

| Maximum roll diameter | mm | 710 |

| Axis travel | mm | 480 ×5 290 |

| Grindstone speed | min-1 | 450 ~ 1 200 |

| Roll rotation speed | min-1 | 7 ~ 300 |

| Grindstone drive motor | kW | 2.2 ~ 15(cont.) |

Wheel Travers

KWA series

| Track record | Unit | KWA |

|---|---|---|

| Maximum roll diameter | mm | 2 400 |

| Axis travel | mm | 910 ×11 730 |

| Grindstone speed | min-1 | 2 ~ 80 |

| Roll rotation speed | min-1 | 500 ~ 1 500 |

| Grindstone drive motor | kW | 35 ~ 110(cont.) |

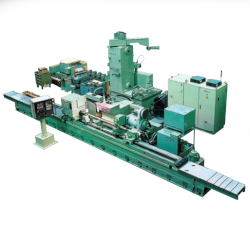

Gear Cutting Machine

Gear Cutting Machine

HSC series

| Track record | Unit | HSC-130L | HSC-200/300 | HSC-400/450 |

|---|---|---|---|---|

| Type of gear wheel | External gear/Internal gear | |||

| Maximum module | 25 | |||

| Table diameter | mm | 1 100 | 1 630 | 4 500 |

| Main drive motor | kW | 26(cont.) | 45(cont.) | 55(cont.) |

Gun Drill Machine

Gun Drill Machine

FBH series

| Track record | Unit | FBH |

|---|---|---|

| Maximum hole diameter | mm | 145 ~ 230 |

| Maximum hole length | mm | 1 200 |

| Spindle drive motor | kW | 55(cont.) |

Gun Drill Machine

Gun Drill Machine

BTA Type

DBH series

| Track record | Unit | DBH |

|---|---|---|

| Maximum hole diameter | mm | 20~400 |

| Maximum hole length | mm | 1 000 ~ 11 000 |

| Spindle drive motor | kW | 55(cont.) |

Gun Drill and Milling Machine

Gun Drill and Milling Machine

MGC series

| Track record | Unit | MGC -315 | |||

|---|---|---|---|---|---|

| P15 × 30 | R14 × 16 | R20 × 25 | |||

|

Table size |

mm |

P 1 500

× 3 000 |

R 1 400

× 1 600 |

R 2 000

× 2 500 |

|

| Drill diameter | GD | mm | 3 ~ 30 | ||

| Drilling length | GD | mm | 1 500 | ||

|

Spindle speed |

GD | min-1 | 245 ~ 6 000 | ||

| M | min-1 | 5 ~ 3 000 | |||

|

Spindle power |

GD | kW | 7.5 | ||

| M | kW | 22 | |||

| Vertical travel of head (Y-axis) |

|

mm | 1 400 | ||

| Holizontal travel of column (W-axis) |

|

mm | 1 100 | ||

| Machine Weight |

|

kg | 25 000 | 25 000 | 26 500 |

P:Plane R:Rotary