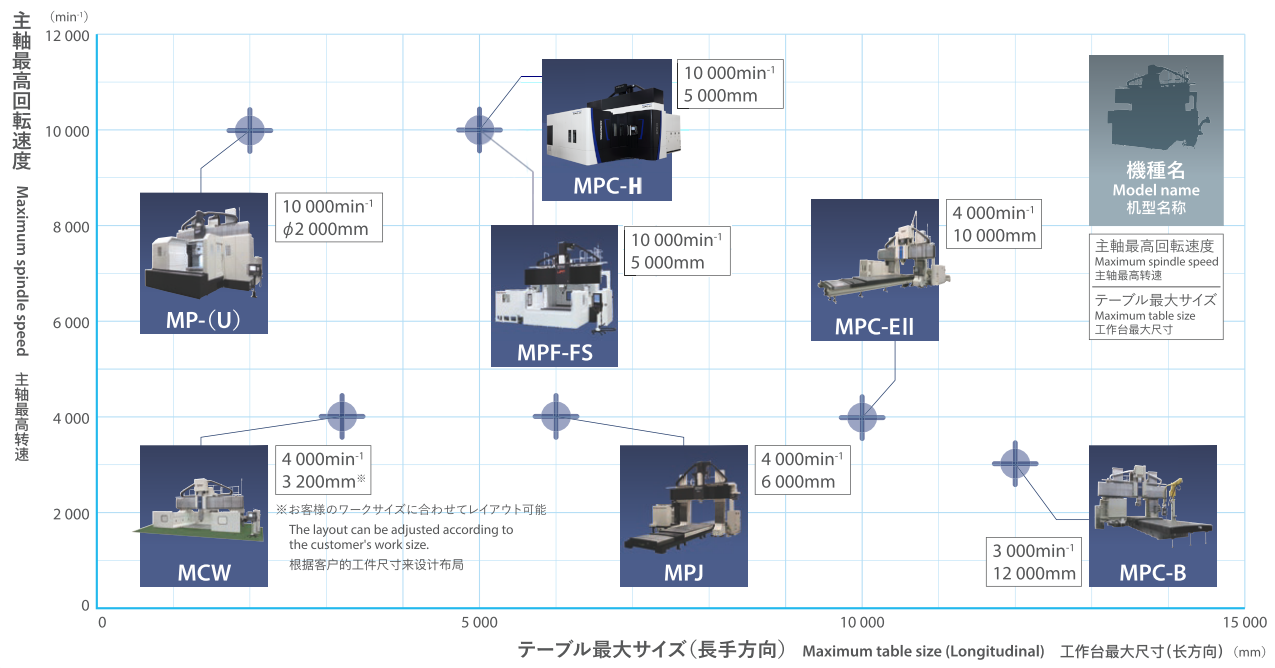

DoubleColumn Type Machining Center

Line-up Map

Processing method,Processed surface

By type

Planomiller Type : MPC-B series MPC-EⅡ series MPC-H series MPJ series

A general longitudinal (X-axis) table movement type double-column machining center.

We offer a wide range of table sizes and gate widths that can be selected according to the workpiece to be processed by the customer, from plates to tall workpieces.

Vertical machining centerType: MPF-FS series

Compared to general vertical machining, it saves space and enables high-speed, high-efficiency machining.

The integrated column structure provides high rigidity, and five-sided machining is possible by using an attachment (OP).

cross rail Feed Type:

MCW series

No.1 in customizability with a wide variety of table types,sizes and spindles.

X-axis drive is cross rail traverse,which saves space compared to table movement.

Multi-tasking machine :

MP-(U) series

5-axis machining is possible with position control of the circular table and 4-axis head.

Multi-tasking machine that adds a turning function to aDouble-column machine with an AAC-capable spindle head.

Features

Contributing to mold machining with high-speed spindles

MPF-FS series

Spindle maximum speed: 10 000min-1

When there is no problem within the range of 3-axis machining and you want to reduce the installation area of the space as much as possible.

MPC-H series

[Standard] Max Rotation of Snout: 10 000min-1

[OP] High-speed snout, maximum rpm of 5-axis head: 20 000min-1

Space saving

MPF-FS series

Compared to general vertical machining center,this machine saves space and enables high-speed,high-efficiency machinung.

MCW series

Space saving compared to the plano mirror type due to table-fixed cross rail movement (X-axis)

Multitasking machine with two faces

MP-(U)series

5-axis machining is possible with position control of the circular table and 4-axis head.

Dual role with milling and turning functions

Movie

We will show you videos of double-column machining centers that are active in various industries.

In the second half, we introduce the much-talked-about processing technology [FSW (friction expansion welding)].

Play on YouTube (5minutes 5 seconds)

Attachment

| Top surface | side surface | B-axis swivel | C-axis swivel | |

|---|---|---|---|---|

|

Snout |

〇 | |||

|

30°・45° head |

30°・45° Fixed |

|||

| Five-sided machining head |

〇 | 〇 | Every 90° [every 5° or 1°] | |

| Hyper angle head |

〇 | Every 90°[every 5° or 1°] | ||

| Angle head | 〇 | Every 5° or 1°] | ||

| 1° index head |

〇 | 〇 | Every 1° | Every 5° or 1° |

| 4 axis head | 〇 | 〇 |

Continuous indexing |

|

| 5 axis head | 〇 | 〇 |

Continuous indexing |

Continuous indexing |

Click here for details of each model

Digital Twin Factory