AM example using ZK series

Rocket engine part

| AM sample dimensions | 8dia.×H3in |

|---|---|

| AM sample weight | 5lb. |

| Deposition time | 18hrs. |

| Material | 718Alloy |

Fan case

| AM sample dimensions | 28dia.×H15.7×T0.4in |

|---|---|

| AM sample weight | 123lb. |

| Deposition time | 71hrs. |

| Material | 718Alloy |

Reverse Engineering sample: REIWA

| AM sample dimensions | 8.3×11.7in |

|---|---|

| Deposition time | 5hrs. |

| Material | 718Alloy |

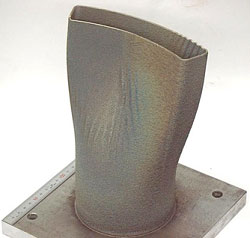

Simultaneous 5-axis deposition: Duct

| AM sample dimensions | 4.3dia.×H8.5in |

|---|---|

| Deposition time | 3.5hrs. |

| Material | 718Alloy |

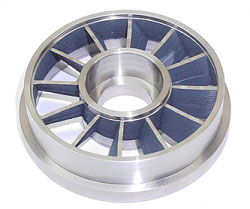

AM example under non-oxidizing atmosphere : Stator vane

| AM sample dimensions | 4.3dia.×H0.8in |

|---|---|

| Deposition time | 4hrs. |

| Material | Ti-6Al-4V |

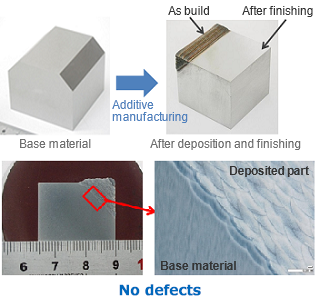

Repair Examples

Advantages

-

Dense structure

-

CAD/CAM for optimal path

-

NC control for stabilization and automation

Higher Quality, Less Manpower, Higher Productivity

| Base material | SKD61 |

|---|---|

| Deposited material | SKD61 |

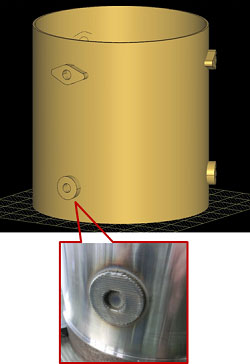

Examples of partial deposition

Advantages of partial deposition

-

Significantly less part material weights and machining time

-

Higher strength than welding (linear welding)

-

Enables partial deposition using different types of materials

-

Repairs for extending lifespan and reducing costs