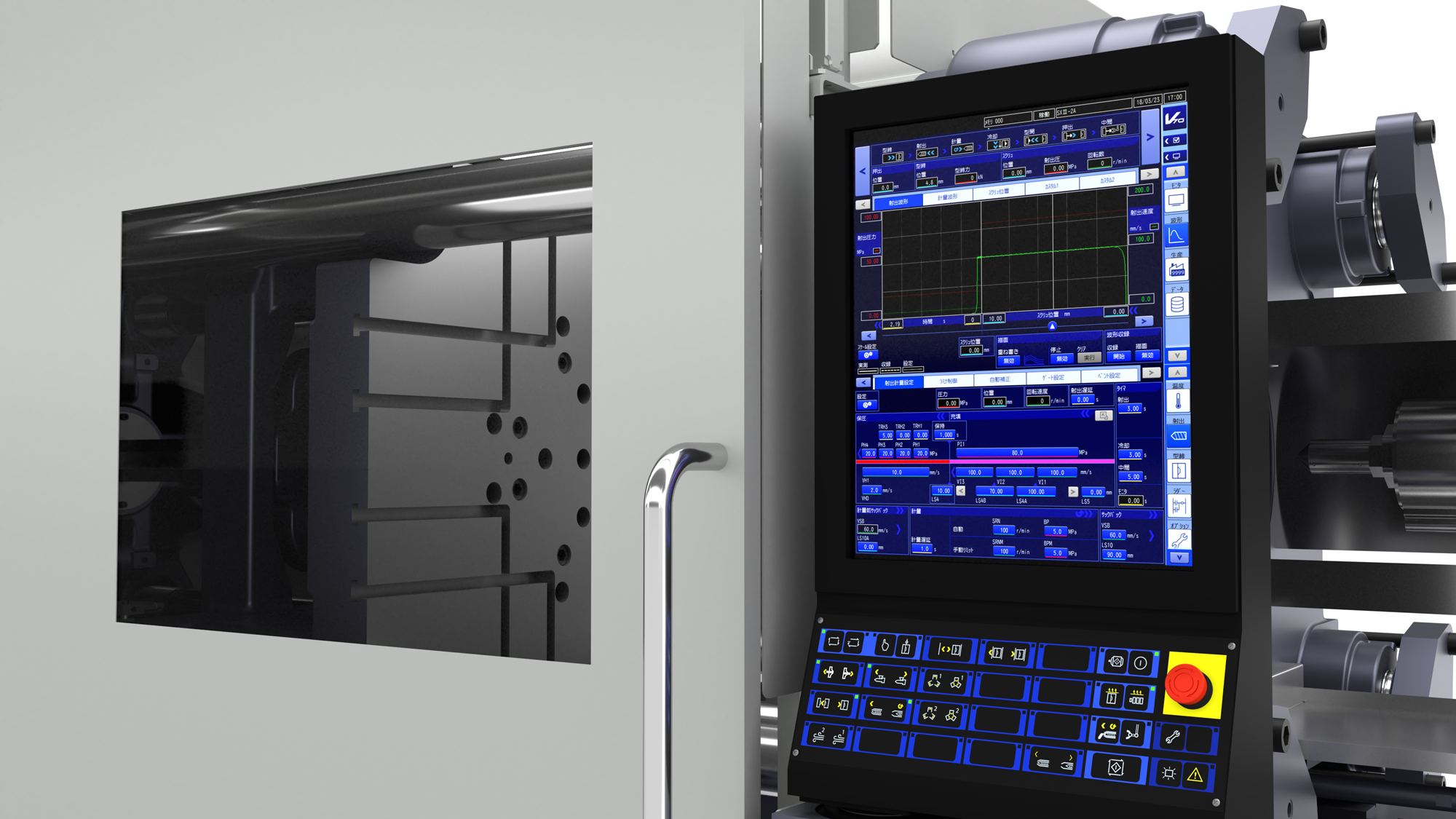

INJECTVISOR V70

Equipped with a 19 inch large-screen , “legibility,” “operability,” and “setting exibility”are drastically improved. has been thoroughly incorporated into the unit to drastically improve customer productivity.

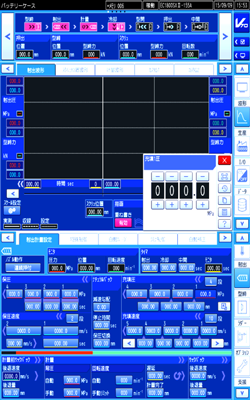

Equipped with two 19-inch resistive film type touch panels in top-bottom configuration

Equipped with two 19-inch resistive film type touch panels in top-bottom

configuration, icon menu legibility, ease of condition setting, and operation customizing function.

This is a controller with a high degree of setting flexibility to meet the various needs of customers.

INDUSTROL

“INDUSTROL,” a new function allows you to preconfigure and execute the die/molding conditions for the next process and process after the next process, as well as the die changing process for each die through "production plan setting," "inter-process setup setting" and "free program purge.

Customized operation

With injection molding machines thus far, the extrusion, coremolding, and air-blowing actions were limited in scope ofselection, so special operations required new designs and screen configurations.

The Operations Customization Function,a new function of the “INJECTVISOR V70,” allows you to

intuitively move the icon on the performance chart enabling almost infinite pattern formation.

Plugin functions

The “INJECTVISOR V70” has improved on former plugin functions and has many streamlining functions, as well as external device control, monitoring, and communication functions, contributing to raising productivity through centralized control of conditions.

Traceability, Card authentication, Facial authentication (security)

“INJECTVISOR V70” is a controller that is not limited to extensibility of the molding machine, but is endowed with security functions such as product traceability and in-process risk reduction, and is replete with “connecting” and “collecting” functions by connecting various sensors.

|

|

|