Shibaura Machine:

The origin of manufacturing Story 2

Make the world’s most precise gears.

The Hobbing Machine Committee was formed in 1952.

This was an internal project created for the purpose of manufacturing

the first domestically produced large hobbing machine.

This was done not in response to receiving an order for such a machine,

but as an independent company project and an advance investment in the future.

Under the strong leadership of our president at the time,

the entire company worked with intense energy to move the project forward.

The next year, in 1953, the HRS-500 master gear hobbing machine,

whose main operation was milling master worm gears, was completed.

The first component produced was the ring gear for a large vertical boring and turning mill

used to machine turbine blades for the Sakuma Dam, a symbol of Japan’s reconstruction from WWII.

The measured values already surpassed what was then the world’s highest level of precision,

but with the addition of more machine innovations,

successive master gear hobbing machines replaced the master worm wheel with even higher precision versions.

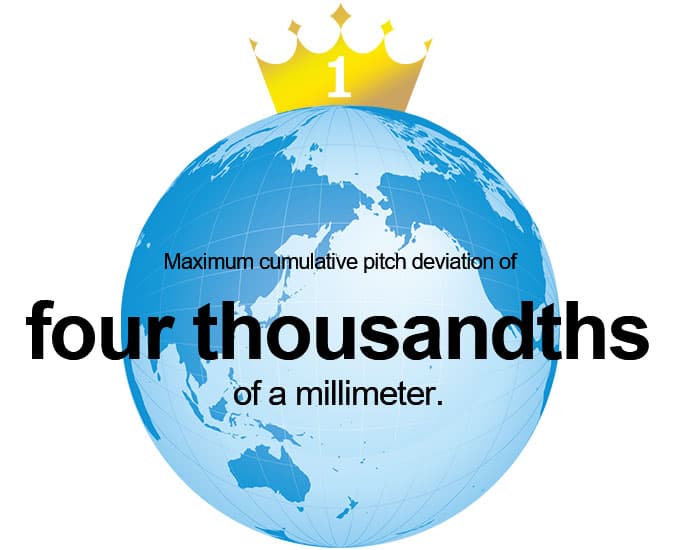

The seventh iteration of the master worm wheel achieved the world’s highest precision

with a maximum cumulative pitch deviation of four thousandths of a millimeter.

We conceived something which did not exist in the world,

and pursued the highest world standard without compromise. This is also a part of Shibaura’s spirit of manufacturing.

The seventh iteration of the master worm wheel is a symbol of this;

a large hobbing machine with superior precision still does not exist anywhere in the world.