High Performance CNC Controller

CNC system TOSNUC 999

CNCSHAPE (Shape recognition preview positioning control: Patent granted)

- Combining with the preview positioning control function, high performance contouring control with remarkable data traceability can be realized.

- Controls the two modes for rough finishing and fine finishing.

- Separate adjustment of each axis acceleration or deceleration according to each axis inertia.

- Pre-reads the data of 1800 successive blocks of tool path according to blocks of very short line of tool path.

- Equipped with fluent control function for smooth interpolation of uneven point-to-point data. When processing successive blocks of short line of tool path at high speed, geometrical errors caused by impacts at corners, or by a delay in the servo system can be eliminated, thus assuring precise machining operations.

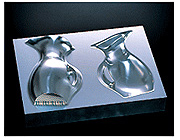

Workpiece material: AI 5052

8 mm diameter ball end mill

N=8 000min-1

F=2 000mm/min

Pick feed=0.2mm

SF function (Patent granted)

Controls and maintains the optimum spindle speed and feedrate per revolution according to ever-changing contact points during cutting of a free-form surface with a ball end mill.

Zone machining function (Patent granted)

When a zone is specified beforehand in die and mold milling operation, the following changes can be made easily for inside or outside the zone, without modifying the original program.

- Change in depth of cut in Z-axis direction.

- Change of cutting conditions.

- Change in both depth of cut in Z-axis direction and cutting conditions.

NURBS interpolation

- High-speed processing of a spline curve defined by CAM.

- Smooth interpolation with spline curve.

A free-form surface can be machined smoothly by commanding three-dimensional curve data and executing curve interpolation on the CNC system.

A polyhedron produced in linear interpolation becomes a fluent curve in NURBS interpolation.

LAN Linkage

- LAN linkage allows high-speed data transfer (10 Mbps).

- Incorporates a compact flash memory (max. 2 GB).

- Reserves programs by the NEXUS schedule function.

Direct sculpture tester

When a measuring command is given while the touch probe is mounted on the spindle, a machined free-form surface can be measured.

- A measuring command for spindle normal direction can be given at each measuring point.

- Errors of surface thickness of a machined free-form surface can be displayed in Excel format.

- After machining, a machined surface can be measured on the machine without additional setup.

Non-linear compensation control function (Patent pending)

Non-linear compensation control I and II are functionally upgraded to minimize quadrant projection during high-speed circularcutting operation. Non-linear compensation control III has been developed to further reduce such projection. Thanks to this function, higher accuracy and higher quality control are now available for die and mold machining operations.

Transfer speed (Baudrate)

The SHAPE function is available to speedily process the data of short line of tool path as in die and mold machining operation. By utilizing this function and to consecutively transfer the NC data at high speed, the following functions are provided.

- Compact flash (CF): Baudrate 38.4 kbps

- USB memory 115.2kbps

- Remote buffer operation (option): Baudrate 600 - 115.2 kbps

- DNC operation (option): Baudrate 115.2 kbps (max.)