Next-generation Die & Mold function

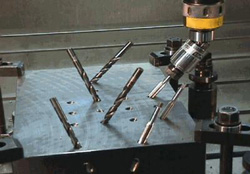

Flex-drill function (Inclined hole machining)

Inclined holes which are generally processed on a 5-axis machine, can be machined instead on a 3-axis machine with this exceptional tool and feature. The special tool holder and CNC program make it easily possible to machine inclined holes at any angle within a range, and eliminate any costly setup time.

5-axis machining on 3-axis machine !

Application:

Cooling holes "water lines" on die and mold, and angular pin holes

Holes inclined from 0 to 40 degrees to the vertical plane.

Simple g code command in one block is sufficient to execute the cycle.

G260 X___ Y___ Z___ B___ C___ F___

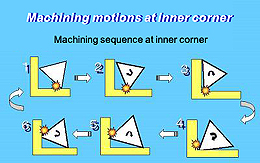

Sharp inner corner machining function

Square corners in pockets are possible to machine with a special tool.

No stock left at inner corner

Application:

- Sharp inner corners in pockets

- Small radius round corner in deep pockets or grooves

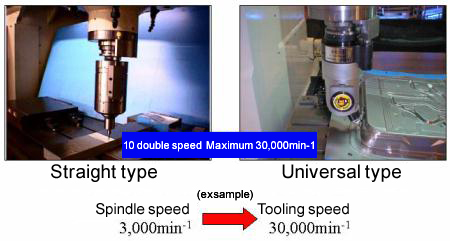

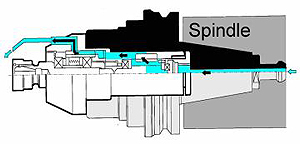

Power-flex (High speed head with integrated power generator)

The spindle on the head is directly driven by a motor which is electrically connected to the power generator integrated in the head body without wiring for power supply. The spindle speed on the head is 10 times that of the spindle speed on the basic machine. (Maximum speed is 30,000 min-1)

The head converts the conventional machine to the high speed machine !!

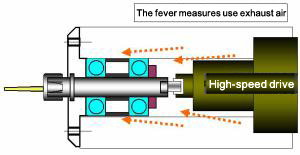

- Easy maintenance !

Spindle unit is a cartridge type that facilitates a replacement if required at maintenance. - Spindle is cooled by exhaust air from the head.

- No lubrication oil or cooling unit is required.

Wind-Miller (Air drive tool)

This is an air driven toolholder that is mounted in our ATC magazine, and is supplied with air through the center of the tool for drive power. (Maximum speed is 40,000 min-1)

Wind-Miller with chip blow nozzle

- Air driven !

Air drive mechanism for high speed is integrated in the holder - Spindle unit is a cartridge type in order to make it easy to replace once at maintenance on the Power-flex.